As a bulk material handler, you know that just because a conveyor system seems to be functioning well, complications can still be forming within it. If the system is not inspected and maintained correctly, what begins as a small problem can turn into a major one that forces a shutdown and creates lost production and, worse, lost revenue.

Prevailing wisdom advocates planned and scheduled conveyor maintenance. Not having a program – or having one and not properly managing it – can lead to malfunction and stoppage that cut into operational budgets. Curative repair costs can double or even triple the expense of preventive maintenance.

Efficient bulk material handlers keep conveyor system maintenance a priority. Many have a conveyor maintenance checklist and perform periodic conveyor inspections.

Bulk material handlers who focus on proactive prevention:

- reduce downtime

- increase output

- extend the life of equipment

- lower the risk of high-priced repair work

- reinforce optimal customer service

Benetech: Conveyor Maintenance and More

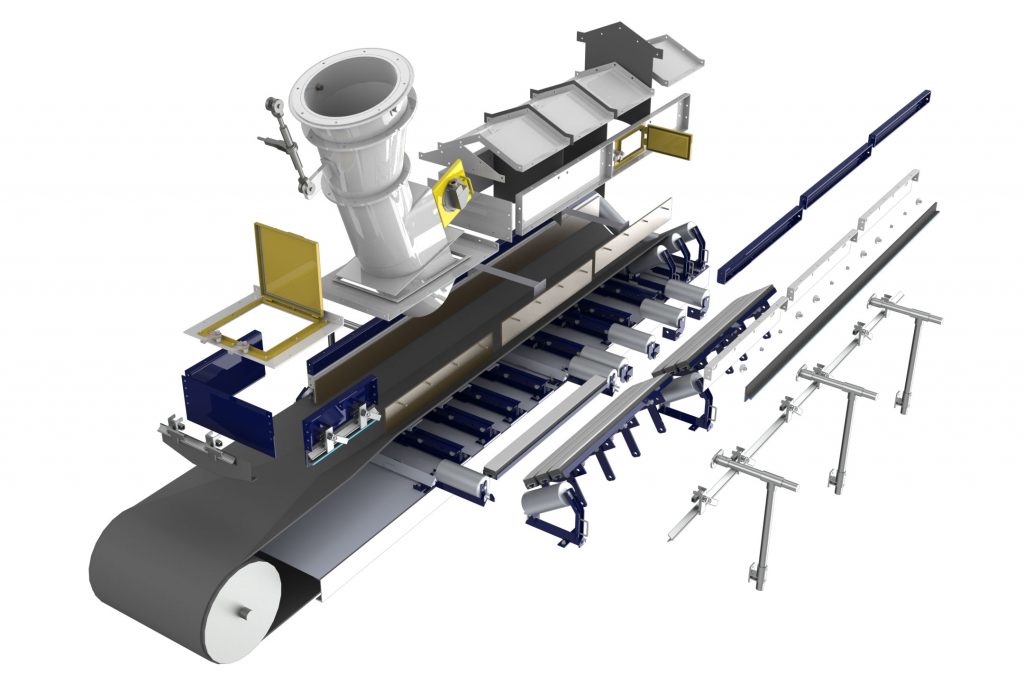

As specialists in bulk material handling, Benetech supports you with advanced conveyor maintenance solutions. We contribute to uninterrupted production with less spillage and pluggage; less wear and airborne dust; improved material flow; and greater regulatory compliance for avoiding citations and fines.

Working with us proactively, you can identify potential setbacks early and fix them. Benetech conveyor maintenance and repair includes any needed solution such as audits/inspections, adjustments, installation of equipment and replacement of parts.

In addition to preventing and controlling challenges such as pluggage, carryback and mistracking, Benetech conveyor belt maintenance helps you avoid more-serious hazards such as explosions and fires.

Your advantage with us goes beyond thorough conveyor maintenance. Benetech can also extend your maintenance intervals while further enhancing production.

With us, you can upgrade your older, labor-intensive equipment and systems to advanced solutions such as:

- engineered transfer systems that control material flow and lessen impact against belts, chute walls, stringers and idlers

- inspection doors that allow personnel to safely and easily access all areas to ensure proper conditions and functioning

- material flow enhancers that restrict build-up and pluggage

- proper impact beds and trackers that keep the conveyor belt centered and protected

- belt cleaners that prevent spillage and carryback

Our upgrades boost your capabilities and decrease the frequency and need for regular conveyor inspections and maintenance. Because we equip you with the most current components, technologies and processes, you develop fewer problems and schedule less downtime. You save time and money with a safer, fully operative system.

Move More Material for Longer Periods with Fewer Delays

Benetech is your long-term solution for problem prevention in material handling. Contact us at (630) 844-1300 today to speak with a Benetech specialist about our conveyor system maintenance, repair and inspections.

Posted in Maintenance