Effectively Removing Built-up & Carryback Material

The proper cleaning of conveyor belts is a significant problem in most plants. After the material has been discharged, particles adhering to the belt (carry-back) must be removed to prevent spillage along with the conveyor and build-up material on the return rollers. The material build-up will cause the belt to mistrack and eventually damage its edges. In addition, spillage around the conveyor will lead to extra maintenance and clean-up costs.

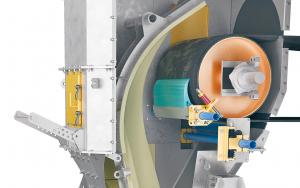

Benetech’s conveyor belt cleaning solutions include primary, secondary, and specialty cleaners or belt scrapers that solve carry-back issues. Created to keep production moving and extend the life of your belt, our conveyor belt cleaning systems provide superb cleaning efficiency that minimizes maintenance.

Benetech’s conveyor belt cleaning solutions are made for all transported materials regardless of their hardness, shape, or abrasiveness. With our conveyor belt cleaning systems, your business can manage everything from wood chips, recycled paper, and garbage to iron pellets, coal, and crushed rock.

Belt Cleaners

Primary Belt Cleaners

Secondary Belt Cleaners

Specialty Belt Cleaners

Replacement Blades

Wash Box ™

We’re ready to assist you with an application-specific conveyor belt cleaning solution. Find out more about our primary belt cleaners, secondary belt cleaners, specialty belt cleaners, and replacement blades here at our website or contact us today at (630) 844-1300.