Conveyor Belt Cleaning Solutions: MaxClean Secondary Cleaners

Benetech’s MaxClean secondary conveyor belt cleaning systems are installed right behind the drive pulley. Available in different designs, they usually are used with a pre-cleaner for the most excellent efficiency. However, they also can be used as a stand-alone conveyor belt cleaning solution if the transported material is dry and fine.

BES1 – Best Seller

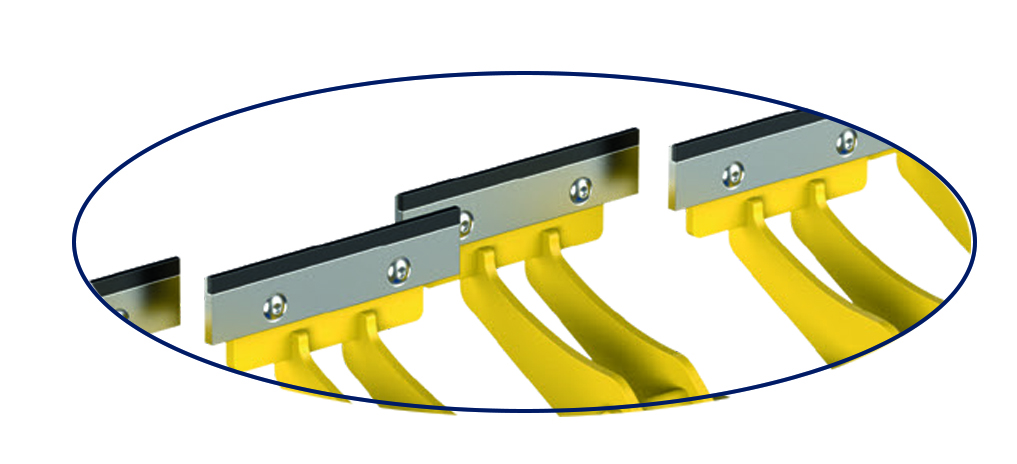

The BES1’s blade holder keeps the center of the conveyor belt scraper blade on the belt, making it ideal for cupped or worn belts. The blade ends push down for even pressure across the blade, which also arcs into the center as it wears to maintain blade-to-belt contact. The conveyor belt scraper blade pivots and bends around a central pivot, allowing it to conform to worn, uneven belts.

A one-piece rubber blade with tungsten carbide tips features flaps that ensure carry-back slides away from the blade and doesn’t build up. The conveyor belt scraper blade also is available in tri-layer, high-temp, dual-layer, ceramic-bead, and chemical-resistant rubber for superb water removal. A Rosta joint tensioner absorbs severe impacts as well.

With an overall height of just 5”, the BES1’s low-profile modular design works great in confined-space chutes.

Other advantages of the BES1 conveyor belt cleaning system include:

- Torsion Arm Segments™ that allows the blade to conform to the belt and move away from obstructions

- Threaded rods for easily moving the cleaner up to the belt or down for maintenance

- Quick and easy blade installation and replacement

BXS5

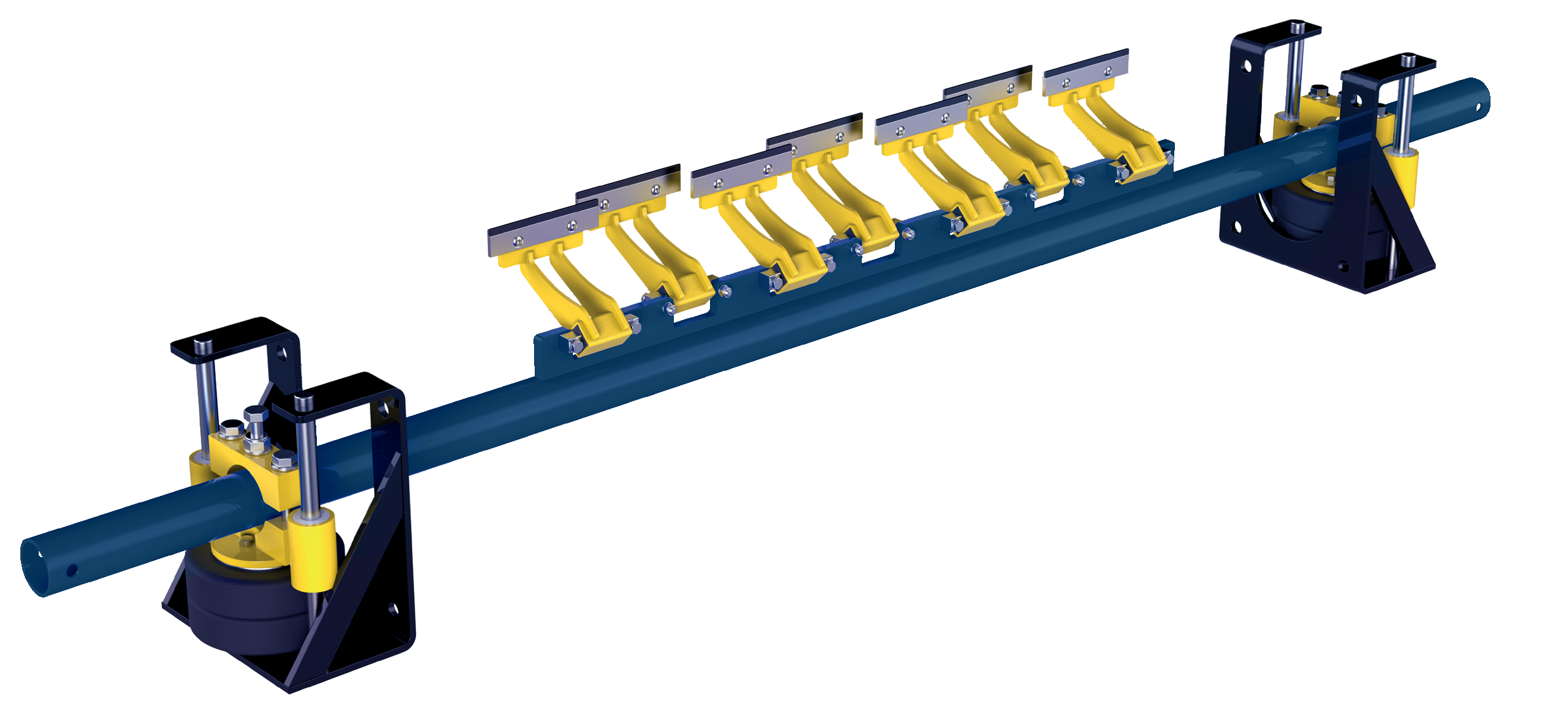

![]() High-efficiency blades with superior wear resistance- available in tungsten carbide or ceramic

High-efficiency blades with superior wear resistance- available in tungsten carbide or ceramic- Individual self-adjusting blades via torsion element for maintaining blade-to-belt contact

- Double tensioning equipment for better pressure distribution

- Ideal for use on spliced belts- allows mechanical splices to pass without any damage

- Overlapping blades for more efficient scraping

- Superior service life

We’re ready to assist you with the right MaxClean secondary conveyor belt cleaning solution for your material handling. Contact us at (630) 844-1300 today to speak with a Benetech specialist.

High-efficiency blades with superior wear resistance- available in tungsten carbide or ceramic

High-efficiency blades with superior wear resistance- available in tungsten carbide or ceramic