MaxZone Safe+™ – Silica Dust Control System

Combating Respirable Crystalline Silica (RCS) Dust Exposure

Researchers at the National Institute for Occupational Safety and Health (NIOSH) have identified Respirable Crystalline Silica (RCS) as a particularly serious exposure risk. RCS is associated with operations, such as handling cement, aggregate, coal, limestone, and frac sand associated with hydraulic fracturing operations during oil and gas extraction.

Researchers at the National Institute for Occupational Safety and Health (NIOSH) have identified Respirable Crystalline Silica (RCS) as a particularly serious exposure risk. RCS is associated with operations, such as handling cement, aggregate, coal, limestone, and frac sand associated with hydraulic fracturing operations during oil and gas extraction.

The process of bulk material handling utilizing conveyor belt systems typically generates dust at loading interchanges, transfer points, inclines, and at discharges from skirting systems. Reducing dust especially in these areas can reduce worker exposure to dust of various materials that contain Respirable Crystalline Silica (RCS). It is essential to limit these exposures to workers.

Typical airborne dust generated at these transfer points can result in poor air quality and exposure exceeding worker respirable MSHA dust limitations.

In addition to respirable dust, impact to area safety, increased equipment maintenance, and costly maintenance are caused by excessive dust. Excessive dust creates build-up in transfer buildings and on conveyor structural members which, under the right conditions, can cause combustion events if the dust is combustible.

Features & Benefits

- Achieved up to 93% dust reduction in silica dust testing

- Captures a variety of fugitive dust particles, including fine silica dust

- Developed under a Research Collaboration Agreement with NIOSH

- Designed to meet MSHA-compliant standards

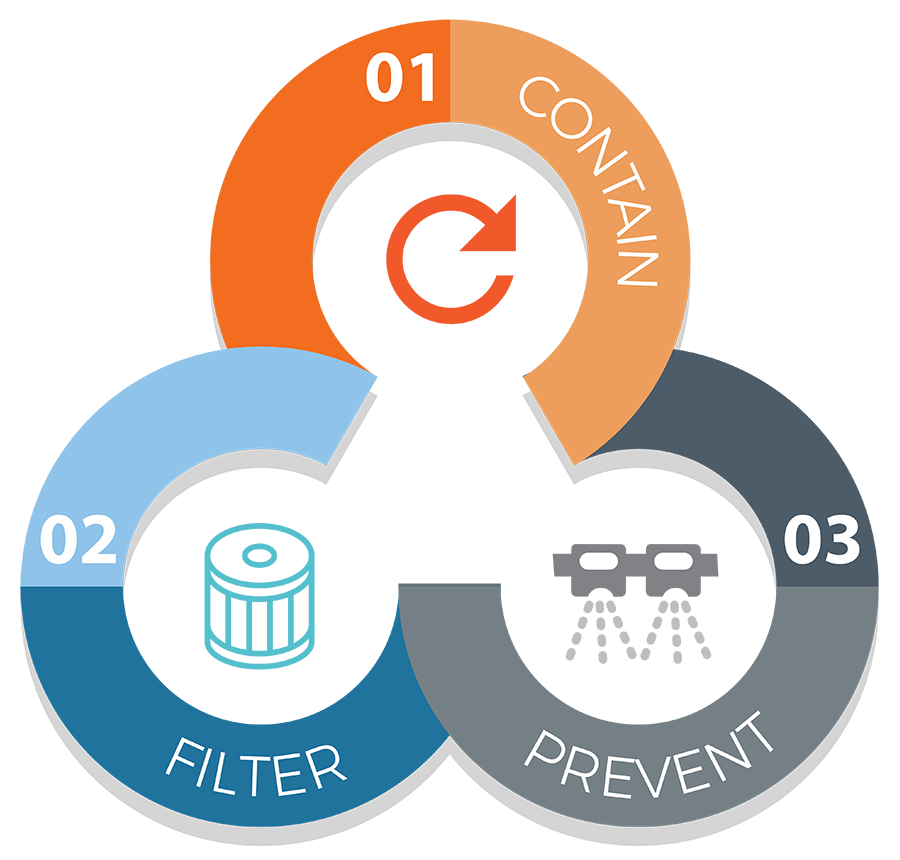

![MaxZone-Safe-Plus - Contain, Filter, Prevent]() A Powerful Combination of Three Benetech Technologies

A Powerful Combination of Three Benetech Technologies

- CONTAIN:

MaxZone® (Load Zone Containment System)

Benetech’s patented load zone containment featuring a modular skirtboard, XN Liner® wearliners, and sealing system - FILTER:

Dustinator® Plus (Dust Filtration System)

Patent-pending, self-purging, active dust collection and filtration system - PREVENT:

MiniPak (Dust Prevention System)

Applies a non-toxic, bio-degradable, environmentally-friendly chemical binder that does not contaminate product

Benetech’s MaxZone Safe+™ system is a powerful solution to reduce airborne dust specifically combating Respirable Crystalline Silica (RCS) exposure.

The system’s foundation is the MaxZone® Modular Skirtboard System for loading material containment. The Dustinator® Plus – installed on top of the MaxZone – consists of a dust box, self-purging filters, compact blower (active system only), and air tank reservoir. Finally, the MiniPak completes the entire system by chemically preventing airborne dust before the material exits the containment area.

Once the MaxZone Safe+™ is installed and running, the self-purging air filtering system will continuously and automatically clear the filter debris while in operation. Differential pressure sensors monitor the air flow and automatically purge the filter system when needed.

Additionally, the MaxZone Safe+™ system provides a dust prevention application to material discharged from the MaxZone to control dust during the filter purge cycle.

Consult Benetech, Inc. if you have any questions about product application and use. We have the experience and products to provide recommendations for your specific application.

How the MaxZone Safe+™ Dust Control System Works

- Mined material drops onto the receiving belt and is contained within the MaxZone® skirtboard, liner, and seal system.

- Mounted above the discharge end of the MaxZone, the Dustinator® Plus acts as a dust collection system removing nearly all of airborne dust.

- The system energizes an air blower system starting with a conveyor run signal to generate suction to collect material onto four (4) cartridge filters.

- The Dustinator® Plus filtration system uses pressure differential controls to determine when filters are near dust saturation to automatically complete a self-purge cleaning cycle. This cycle cleans the filters and discharges the material back onto the belt.

- Just prior to the dry dust filter purge cycle, a water solenoid valve on the MiniPak is activated providing a binding agent. This system instantly sprays an environmentally-friendly, bio-degradable chemical solution to minimize dust from the filter cleaning cycle.

- The entire sequence repeats, as required, to maintain control of airborne dust.

MaxZone Safe+™ Literature

| Flyer - MaxZone Safe+™ Dust Control | Download |

| Flyer - Dustinator® Plus "Active" System | Download |

| Manual - MaxZone Safe+™ Installation & Operation | Download |

| White Paper - Benetech-NIOSH, Reducing Worker Exposures to Dust and Respirable Crystalline Silica | Download |

| Fact Sheet - MSHA Silica Dust Initiative | Download |

A Powerful Combination of Three Benetech Technologies

A Powerful Combination of Three Benetech Technologies