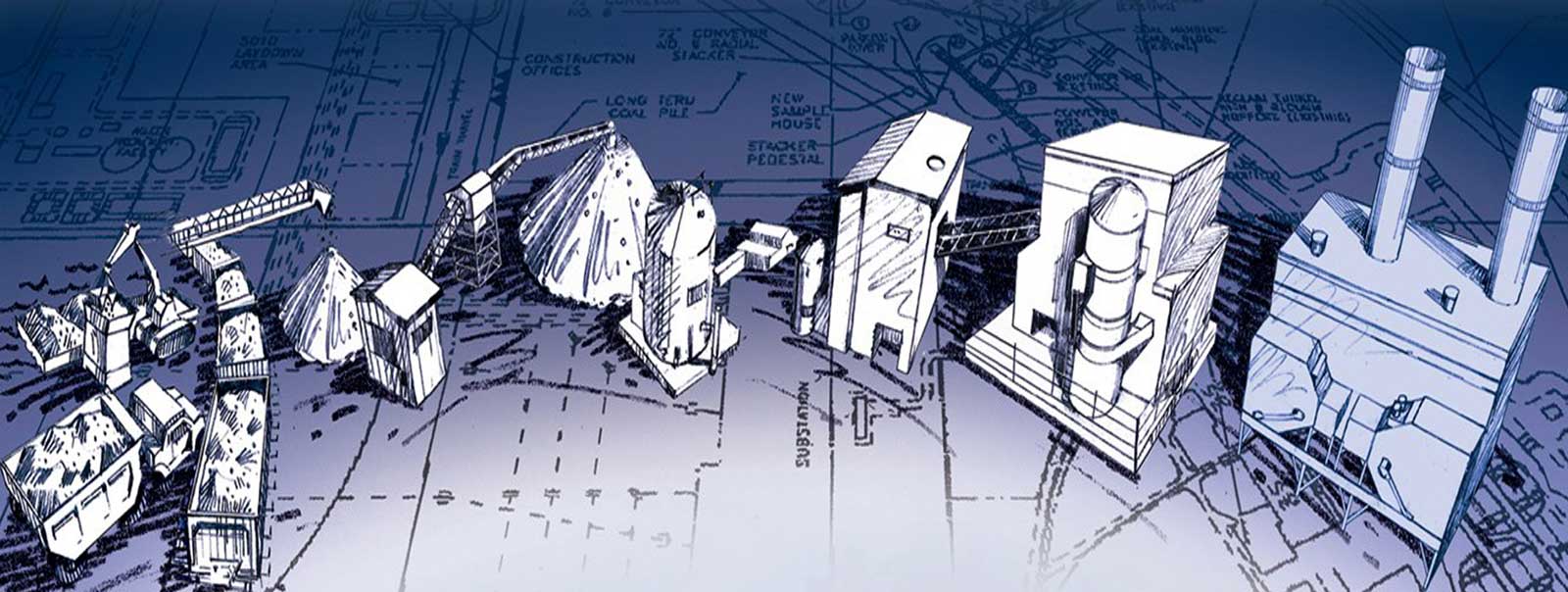

Master Dust Control

Conquering spillage and fugitive dust requires a complete solution throughout your facility.

Benetech understands how, why, when, and where you need to master dust control. We support you with the technology and service for TDM® (Total Dust Management) that helps your operation reach its most significant potential.

Our TDM® Technology & Services

- Regulatory Compliance

- Asset Optimization and Reduced Waste

- Advanced Transfer Systems

- Advanced Conveyor Loading Systems

- Dust Suppression

- Washdown Systems

- Wet Dust Extraction

- Dry Dust Collection

- Containment and Components

- Turnkey Installation/Start-Up

- Engineering Services

- Housekeeping/Maintenance

TDM® (Total Dust Management)

Regulatory Compliance

The Occupational Safety and Health Association (OSHA), the Mine Safety and Health Administration (MSHA), and the Environmental Protection Agency (EPA) all publish rules and guidelines concerning the reduction of respirable and combustible dust. Benetech dust management combines products and technologies to help you comply with regulations while maintaining goodwill with personnel and your community.

Asset Optimization and Reduced Waste Audits

Optimizing operational assets and processes is integral to planning maintenance strategies—proper optimization reduces unplanned downtime, production losses, and unnecessary overtime expense. Benetech’s professional network offers advanced knowledge and capabilities that keep your systems running as efficiently as possible. As a result, you can improve your work environment, productivity, and safety with our team while reducing operating & maintenance costs and risks.

Advanced Transfer Systems

Benetech engineers procure and construct your transfer chutes according to your industrial processing system, including the transfer tower, cascade conveyors, and post-crusher load zones. Rather than control dust passively, we implement a cornerless chute design to restrict its formation while increasing material flow.

Advanced Conveyor Loading Systems

Benetech’s MaxZone® Modular Skirtboard and Belt Support System help you achieve properly aligned transfer point chutes and centered loading with components such as inspection doors, internal wearliners, idlers, impact and support beds, and belt guards and cleaners. The result is much greater dust abatement.

If you cannot replace a load zone chute because of budget and time, our MaxZone Plus® system can support your dust control without the need for permits or shutdowns. Just add it to your existing Benetech XN Liner® System or retrofit it to another containment system.

Dust Suppression

Benetech Dust Suppression applies chemical-solution injections that reduce and even eliminate dust. It also instills systemic solutions such as managing materials that repel water from their surface. It does this by lowering the water’s surface tension to a value closer to the treated material so the water droplets can capture more dust particles.

Washdown Systems

As dust accumulates during production, it becomes airborne and settles in areas high above the floor or hard to see or reach. Hosing them down by hand leads to excessive housekeeping hours and costs. Benetech Washdown Systems help you remove all dust after the material is conveyed. They also minimize water usage and integrate engineered drainage, curbing, and water shielding.

Wet Dust Extraction

Benetech’s wet dust extractor uses energy from a bifurcated fan to encapsulate dust particles into atomized water. This treatment removes 99.7% of dust while eliminating the need for compressed air, belt maintenance, and bag changes. In addition, our Wet Dust Extraction further increases safety by removing the motor from the air stream and preventing bag-house explosions.

Dry Dust Collection

We understand that Wet Dust Extraction may not always be an option depending on material water solubility and budgetary constraints. Our Dry Dust Collection systems combine advanced technology and custom engineering to offer superior safety, cleaning action, and low-pressure efficiency. With Benetech, you both ensure your current dry dust systems run correctly and revitalize their performance and maintainability.

Containment and Components

Proper conveyor containment significantly reduces airborne and fugitive dust, preventing product loss and spillage while improving operational safety and efficiency. Easy to install and maintain, Benetech’s conveyor components provide your systems with the premium support and containment you need for greater dust control.

Turnkey Installation/Start-Up

Benetech specializes in the turnkey engineering, procurement, and construction (EPC) of technologies for all types of bulk material handling.

We guide you through every phase of establishing a complete, integrated system for your operation, including:

- Engineering

- Power Supply

- Concept Planning & Design

- Material Handling

- Installation

- Electrical Control

- Civil/Structural

Engineering Services

Benetech’s professional engineers provide the skill and perspective to custom-design bulk material–handling systems and equipment for your specific plant. Our engineering solutions enhance system performance and reliability, reduce O&M costs and increase safety and efficiency. We also strictly adhere to the latest safety standards and the most current CEMA guidelines.

Housekeeping/Maintenance

Good housekeeping requires more than maintaining a clean environment. It must also reduce or eliminate risks and hazards while making optimal use of hours and costs. Benetech’s products and technologies contribute to excellent industrial workplace safety and easier maintenance for a more efficient, secure operation.