Production Advantages for the Pulp and Paper Industry![Coarse pulp transfer system Coarse pulp transfer system.]()

Competing in today’s pulp and paper market requires optimum performance. Efficient, timely production depends on your plant’s ability to supply what your customers need without setbacks.

During your pulp and paper production, chipping operations, conveyor systems, bins, storage silos, and dust collectors must work reliably while minimizing dust and spillage. In particular, chipping operations, especially those involving dry feedstock, have to meet more stringent safety and environmental standards for dust control at paper mills ever.

Benetech solutions for material handling and dust management at pulp and paper mills help reduce risks such as fires and explosions to ensure maximum output, less maintenance, and a safer, cleaner operation.

Material Handling Issues That Matter to You

Pulp and paper mills face a high risk of dust fires. The plant must have proper dust control and management systems and procedures to maintain steady production at acceptable risk levels. Together with dust generation, the relatively low bulk density of the dust and agglomerations increases fire risk because of an increased surface area and porosity that lets air easily mix with the dust. Whether due to spillage, carryback, or belt mistracking, just one snag can halt your operations.

As a pulp and paper plant operator, you’re especially alert for spillage and fugitive dust concerning transfer chutes and conveyor carryback. Dust and spillage can interfere with production and create hazards. Similarly, worn components such as chutes, cleaners, belts, idlers, trackers, and ploughs can threaten operations. They also prevent the conveyor belt from achieving its design capabilities.

Specialists in Conveyor Systems at Pulp and Paper Plants: Case in Point

Benetech understands what it takes to continue pulp and production at total capacity. We provide you with the assessments and solutions for superior material conveying systems and dust control.

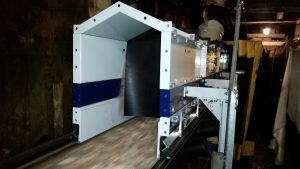

Benetech recently solved a dust-management challenge for a Canadian pulp mill struggling with aging transfer chutes. The existing chutes had not been built with combustible-dust containment in mind and did not control material flow.

The plant faced significant dust, spillage, and pluggage issues. The uncontrolled material was shortening the life of equipment, including the conveyor belt. In addition to increasing efficiency, the plant wanted to reduce combustible dust and improve operational safety.

Benetech partnered with the plant to assess the situation and provide an engineered solution to control the material flow and prevent spillage and dust. At the same time, we would extend the belt life and create a more secure working environment.

Productive and Profitable Pulp and Paper Mill Conveying Systems

You succeed with Benetech because our engineers know your challenges and create custom solutions for them. Whether optimizing your conveyor belt or enhancing your pulp or paper mill dust control, with Benetech you:

- Better manage material flow

- Significantly reduce fugitive dust

- Increase belt, chute, and wearliner life

- Prevent belts from mistracking

- Decrease spillage and carryback

- Improve operational safety

- Cut maintenance time and costs

- Reduce housekeeping time and expenses

In addition to our ADVANTEDGE belt cleaner, we offer an innovative range of solutions for conveyor systems and dust management at pulp and paper mills:

- MaxZone® spillage and dust containment systems

- Belt Support and Containment

- Dust Suppression at loading hoppers, unloading stations, and transfer points

- Clean Sweep Air Cannon Systems

We also work closely with your plant’s personnel to assist with new technologies and proper system support.

Upgrade Your Efficiency and Safety Starting Today

From debarking, chipping, stackout, and conveyors to the digesters, Benetech’s turnkey solutions will keep your systems running efficiently, safely, and profitably. Pulp & Paper production is too important to run the risks of unexpected downtime and excessive maintenance. Further secure your pulp & paper conveying system and plant dust control. Contact us at (630) 844-1300 to speak with a Benetech specialist and see how our integrated services and technologies can help improve your operation by reducing dust, preventing spillage, improving material flow, and ensuring compliance.