Clean Sweep AC − Material Flow Control

Eliminates Build-Up, Keeps Material Free Flowing

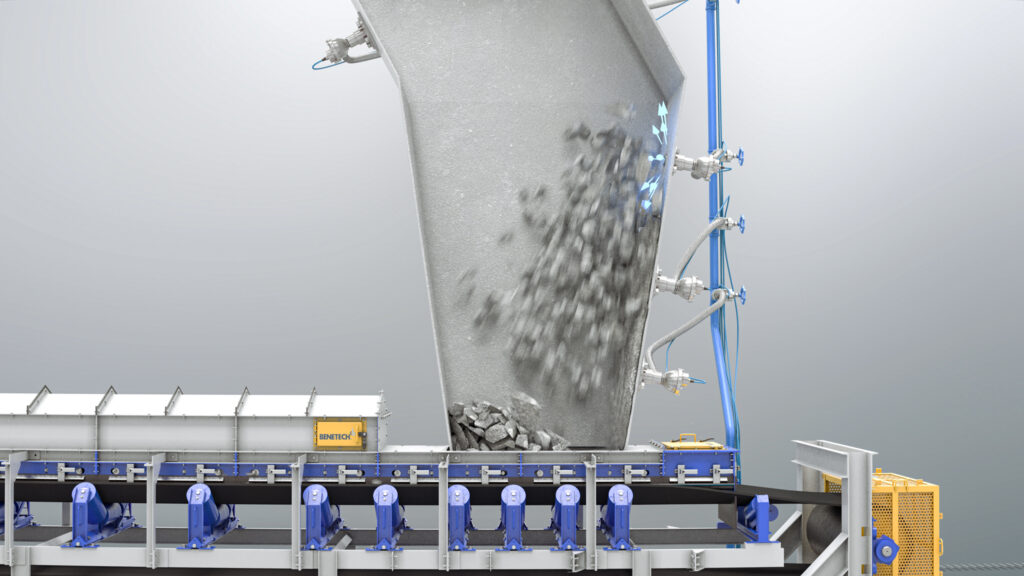

Poor material flow can cause material build-up, halting your production. With the ease of maintenance in mind, Benetech’s engineering team has created the Clean Sweep Air Control to increase material flow by delivering a clean sweep of air, to free blocked or plugged chutes, silos, bins, and hoppers.

In 0.1 sec, the Clean Sweep AC delivers a 3ft radial pulse of air along the chute wall, 360 degrees, to return material to its free-flowing state. Clean Sweep requires 80 – 100 psi of compressed air and operates on 120 VAC single-phase power.

Most bulk material handlers would agree that a perfect day at the plant would include an uninterrupted material flow: no shutdowns, little to no maintenance, nothing but steady production from sun up to sundown.

Clean Sweep eliminates bridging, ratholes, and material handling build-up. Each nozzle emits a high-pressure, high-volume, 360-degree burst of compressed air to lift and sweep stalled material back into the flow stream – clearing the way for higher factory and material handling efficiency.

Distinctly designed for bulk materials, the radial Clean Sweep automatic cleaning system uses standard plant compressed air at 80–100 PSIG to prevent pluggage and eliminate build-up in transfer chutes, bins, hoppers, silos, and bunkers.

Easy to install and maintain, Clean Sweep Air Control is your trouble-free answer to ensuring uninterrupted material flow, especially for wet and sticky substances such as sand and cement. Clean Sweep is the only radial, pneumatic air nozzle cleaning system created for bulk material handling and designed not to damage ceramic-lined chutes.

Keep Material Flowing

- Increase production of material

- Reduce maintenance costs

- Decrease pressure inside silo walls

Material Treated

- Aluminum

- Bentonite

- Cement

- Coal

- Copper

- Fly Ash

- Grain

- Iron Oxide

- Limestone

- Soda Ash

- Shale

- Salt

- Soybeans

- Sugar

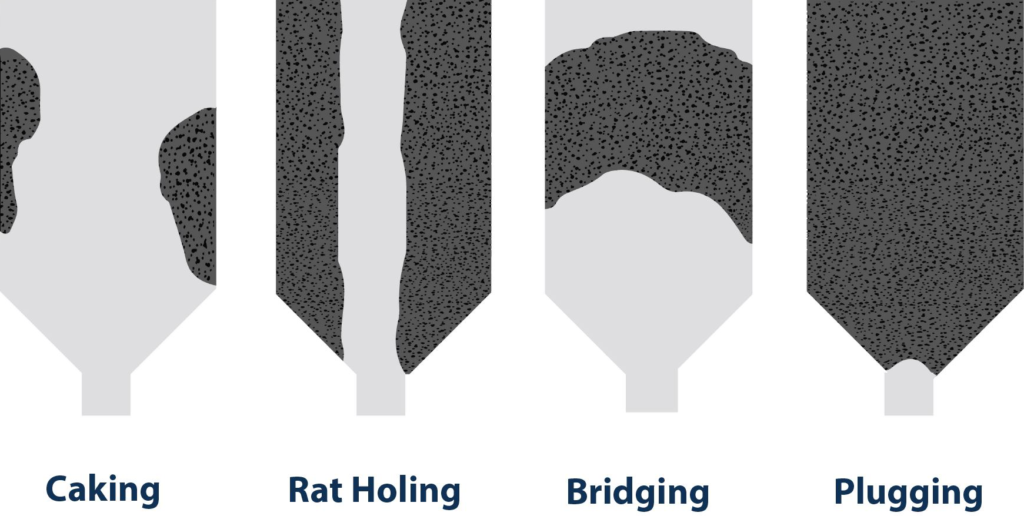

Common Issues Caused by Material Build-Up

Caking – sticky material builds up on the inner wall of the chute, silo, bin, or hopper

Rat Holing – material builds up on the inner walls of the chute, limiting material throughput

Bridging – material bridges across the inner walls of the chute, stopping material flow

Plugging – material sticks to the inner walls causing a complete pluggage stopping material flow

Benefits of the Clean Sweep AC

- Reliable and Safe

- Simple to Install

- Easy Maintenance

- Automatic Cleaning

- Easy Installation

- Cost-Effective Solution

The system’s automatic electronic controls trigger wear-resistant nozzles that sequentially fire precise bursts of plant air supplied through a quick-open/close solenoid valve to achieve less waste and maintenance. Each nozzle directs the air 360°, approximately two feet for 0.1 seconds along the surface of the chute work. In doing so, the Clean Sweep AC impedes material from crusting or layering – rather, it dislodges and breaks up any potential accumulations for easy flushing by gravity and flowing material.

Clean Sweep air control includes a remote air tank and control station for convenient ground-level access. As a result, there is no need to worry about installing large compressed air tanks on chutes, silos, or bunkers.

In addition, the Clean Sweep AC control panel and sequence timers can be located in an area convenient to operations, allowing personnel to make any adjustments needed for changing air pressure and rate of sequencing. The timing sequence and firing rates of the air nozzle can be expanded (supporting up to 45 different nozzles) to accommodate a range of chute configuration changes. The air pressure nozzles are often installed in a precisely sequenced series to impact accumulation significantly. The system can further be timed for specific process conditions or material characteristics. Beyond reducing or eliminating pluggage, the air pressure nozzles help to clear blocked pathways and allow bulk material to resume its normal flow. Factors such as the frequency and amount of air also can be achieved by adjusting the pressure, tank volume, valve design, and nozzle shape.

Plus, unlike air lancing, which can result in injury and insufficient cleaning, Clean Sweep AC cleans automatically and does not require confined-space permits. Read our blog on the Clean Sweep AC for more information.

We’re ready to support you with material flow enhancement that eliminates build-up and ensures pluggage prevention. Contact us at (630) 844-1300 to learn more about Clean Sweep AC.

Clean Sweep Literature

| Flyer - Clean Sweep | Download |

| Manual - Clean Sweep Installation | Download |

| Brochure - Clean Sweep | Download |