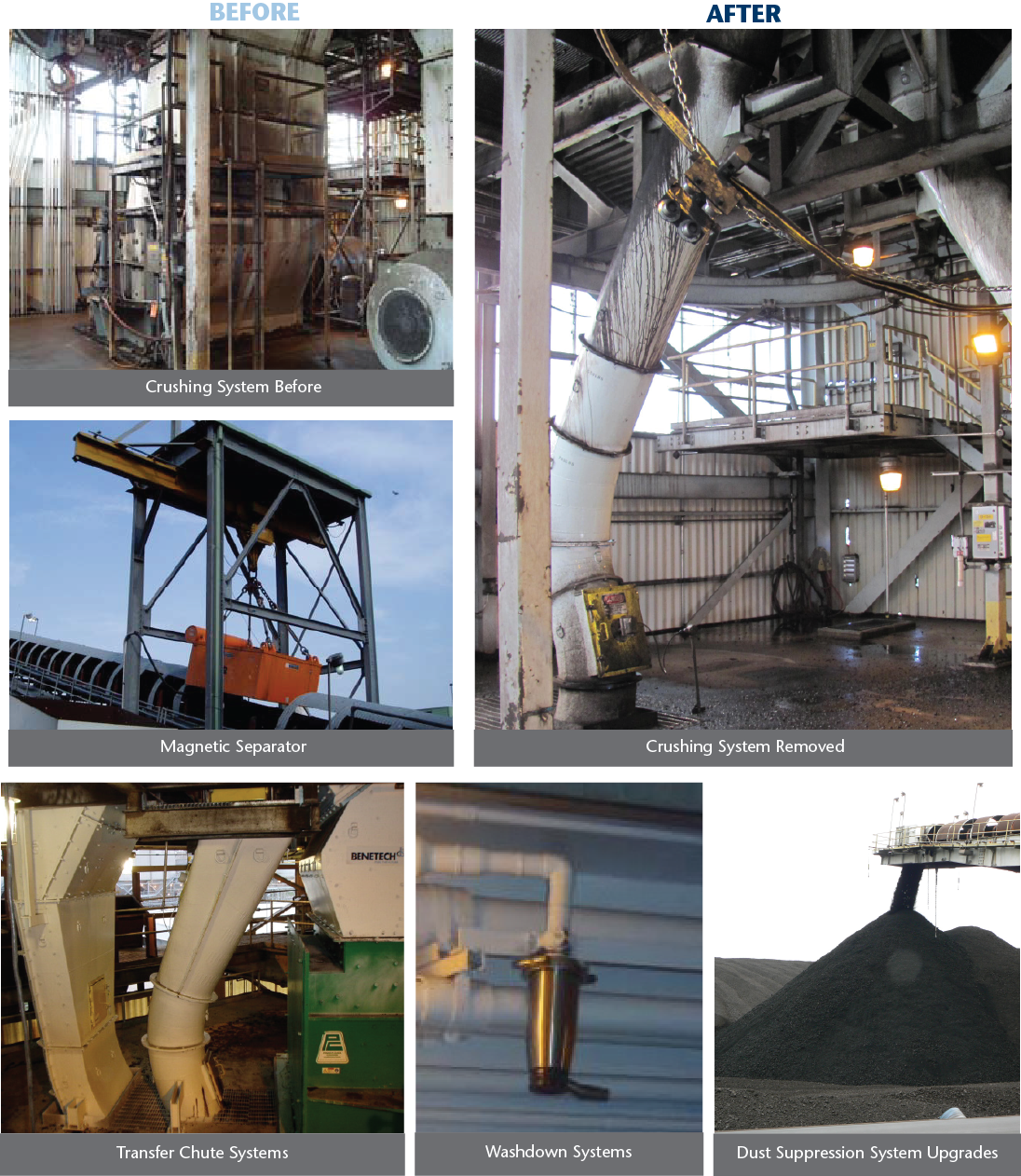

Utility to Upgrade Systems for Improved Safety and Efficiency

Situation

In a process to help the station continue to perform well over the next phase of its life, a large national utility committed resources to be invested in the handling system of one of its Texas generating stations. Benetech did an initial assessment to assess the station’s condition and help the station prioritize projects to handle current operations and challenges.

Project Profile

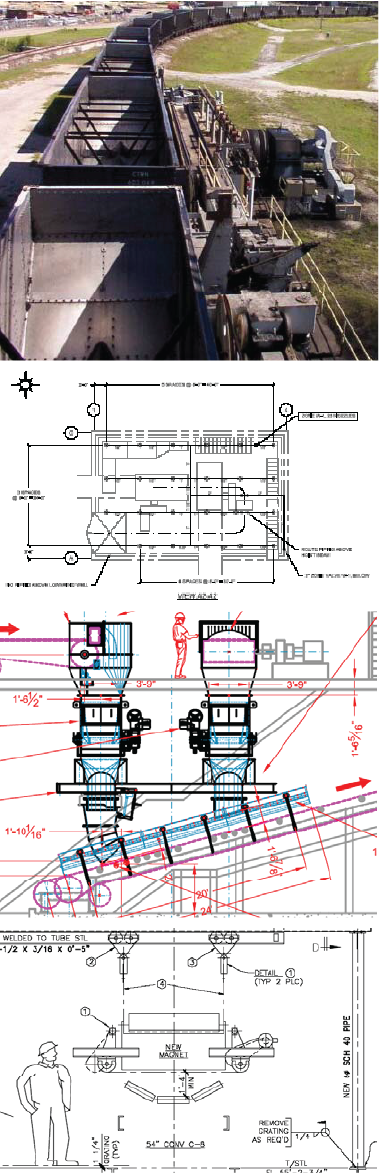

This station has multiple units, with independent rail unloading systems and material handling systems. All coal is brought in by rail from the Powder River Basin, and the plant consumes several million tons per year. Challenges to upgrading the system include limited windows to perform the upgrades, so recommendations and designs need to consider this.

The Benetech Approach

Benetech’s Plant Professional group completed an initial assessment for all areas of coal handling at the station. This allowed discussions with plant personnel on means to divide the work into reasonable sections and focus on the areas to achieve the most benefit first. The assessment team consisted of experts in coal handling, operations, mechanical design, electrical design, structural design, chute work design, and containment design. Each person added to the credibility of the assessment, avoiding the need for individuals to operate outside their area of expertise. Each team member was able to utilize extensive experience in their design specialty and the handling and use of PRB coals.

Based on the initial assessment results, the Plant Professionals team had further discussions with plant personnel. These discussions developed a process customized to the plant’s needs to help them implement the projects. This included having the Plant Professionals group manage Benetech’s Technology designers and a partner engineering firm to develop generic, technology-focused bid packages that the station could use to go out to bids. In all, our team generated over 20 bid packages for the station to use as their budgets allowed.

Solution Achieved

Benetech was able to work with station personnel and develop a go-forward game plan, which allowed the station to evaluate and select several projects to improve safety and efficiency.

New projects continue to move forward on the plan developed with advice and direction as needed by the Plant Professionals team. Benetech continues to support the plant team in the successful implementation of the lifecycle upgrades. Benetech’s technology group has completed several upgrades and has provided management and oversight to ensure the projects meet the intent of the initial project. These projects include:

- Multiple Transfer System Installations

- Redesign of Crusher System

- Washdown System

- Dust Suppression System Upgrades

- Electronic Magnet

- Grizzley Project

- Scale Install