Conveyor Belt Cleaning Systems: How to Prevent Carryback and Improve Performance

The conveyor belt is the workhorse of the load zone. It keeps production moving by transporting tons of bulk material over long distances for extended periods of time. But as belts operate under tough conditions, they inevitably face obstacles that affect both their performance and the overall conveyor system.

One of the biggest challenges is carryback—the fugitive material that sticks to the belt after discharge and clings to the underside, rollers, or pulleys. If not addressed, carryback can cause serious problems, such as:

-

Misalignment as build-up forms on pulleys

-

Increased spillage and dust

-

Higher safety risks for workers

-

Extra housekeeping and maintenance costs

To get the most service life out of a conveyor belt, operators must focus on keeping it clean with a well-engineered conveyor belt cleaning system.

How to Keep Conveyor Belts Clean

Different operations face different carryback challenges depending on the applications. Operations handling steel, gold, aggregate, fertilizer, or other bulk materials will often require tailored belt cleaning strategies. The most effective approach uses conveyor belt cleaners, usually a combination of primary and secondary belt cleaners with an occasional specialty cleaner.

Primary Belt Cleaner

Mounted at the head pulley, the primary belt cleaner scrapes away the bulk of carryback—often two-thirds of the total. Benetech’s BEP1 Primary Belt Cleaner is our best-selling primary cleaner, featuring:

-

Urethane blade for durability without damaging the belt

-

Modular, compact design for adaptable mounting

-

Variable attack angle to reduce blade-edge wear

-

Self-adjusting torsion tensioner for steady cleaning

BEP1

Secondary Belt Cleaner

Installed just past the head pulley or further down the belt line, the secondary belt cleaner removes finer particles that the primary cleaner can miss. Benetech’s BES1 Secondary Belt Cleaner delivers high efficiency with options like tungsten carbide or rubber blades, depending on the belt’s characteristics. Together, primary and secondary cleaners can achieve greater than 90% cleaning efficiency.

Belt cleaner blades and replacement blades can be customized for:

-

Belt width and speed

-

Bulk material characteristics

-

Splice type and pulley diameter

-

Operating temperature

-

One-way or reversing belts

BES1

Specialty Belt Cleaner

In addition to primary and secondary scrapers, some operations benefit from specialty conveyor belt cleaners designed for unique applications. These cleaners provide targeted solutions where standard belt scrapers may not be enough.

-

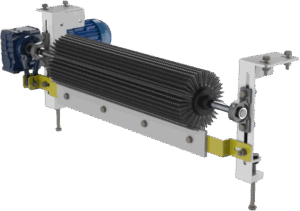

Motorized Brush Cleaners – Ideal for grooved, ribbed, and chevron belts where a standard scraper blade can’t make full contact. The rotating brush sweeps material away from the belt surface for a more thorough clean.

-

Plow Cleaners (V-Plow or Diagonal Plow) – Mounted on the return side of the belt, plows clear material that becomes trapped between the belt and the return pulley, preventing belt damage and reducing wear.

By incorporating specialty cleaners where needed, operators can ensure their conveyor belt cleaning system is fully optimized for their material handling challenges.

Motorized Brush Cleaner

Clean Conveyor Belts Are Good Business

Investing in the right conveyor belt cleaning system pays off in multiple ways:

-

Lower costs and higher profitability – Less time and money spent on housekeeping and clean-up

-

Improved safety – Reduced spillage, dust, and fire hazards for workers

-

Longer equipment life – Prevents damage to belts, idlers, and rollers caused by build-up

-

More recovered material – Keeps bulk product moving in the right direction, not wasted on the return side

-

Energy efficiency – Reduces strain on the head pulley and decreases power consumption

Benetech: Your Total Solution Provider

With Benetech, you get more than products—you get a Total Solution to support your productivity from start to finish. We take pride in partnering with you to deliver full-service solutions, ensuring every step of the process is expertly managed for maximum efficiency and long-term success.

As bulk material handling specialists, the engineers at Benetech understand what can stand in the way of safety and production at your specific facility. Our conveyor belt cleaning systems represent the best of our knowledge, experience, and technology in resolving carryback problems. To learn more about how we can solve yours, reach out to us through our Contact Us Form or call +1 (630) 844-1300 to speak with a specialist.

Posted in Conveyor Belt Cleaners, Conveyor Belts, and Material Handling