Conveyor Wash Box: Remove Carryback & Bulk Material Cross-Contamination

Benetech has developed the conveyor belt wash box to combat carryback and bulk material cross-contamination. The bulk material handling equipment at a typical operation will often move thousands of tons of product every hour of each day. This material is blasted, crushed, ground, conveyed, and transferred by truck or rail. Therefore, material contamination is always a production concern because of the immense amounts and constant activities.

Stagnated material that accumulates can develop into carryback or trapped material that sticks or clings to a conveyor belt after passing over the head pulley. As carryback builds on the conveyor belt and other system components, newly loaded material becomes harder to process. In addition, trapped material that passes under both primary and secondary cleaners begins to spill after later dislodging as well, resulting in lost product, housekeeping problems, and safety hazards, including fugitive dust.

This trapped material often cross-contaminates new material loaded onto it, especially as it becomes thicker, adhesive, and hardened. As the contamination spreads, it compromises material quality and consistency throughout production. Even a minor variation from cross-contamination can affect characteristics such as material color, texture, and size.

Some operators wondering how to avoid cross-contamination of bulk materials might choose a “cure” approach, such as using vibrators to break up carryback. However, more excellent production, profit, and customer service call for a prevention strategy that centers on a more thorough and efficient cleaning system.

How Do I Keep My Conveyor Belt Clean?

The primary way to prohibit material carryback and cross-contamination is to clean the conveyor belt as it passes over the head pulley after the material is discharged from the belt.

The cleaning system is installed as an enclosed, self-contained secondary belt cleaner along the conveyor’s return run. The wash box cleaning system is proven to keep the conveyor belt free of even stubborn sticky material and fines lodged in belt-surface blemishes.

As the conveyor belt enters the wash box, return idlers stabilize the belt. Next, a spray bar uniformly wets the load-carrying width of the belt with water. The water softens the carryback so the wash box’s first belt cleaner, a blade on a tensioner, can remove most of the residual material from the conveyor.

A second belt cleaner in the wash box cleaning system removes any remaining residue. (Beyond the wash box, some systems might include a drying system, such as pressure rollers, squeegee blades, or forced-air blowers.) Residues cleaned from the conveyor belt are drained away from the production area through an outlet funnel under the wash box. The funnel might lead to a disposal unit or a settling reservoir for returning material to the flow.

Because the wash box is mounted on the conveyor frame directly after the return idler, it maintains belt alignment while allowing the remaining moisture to evaporate on the return trip.

The wash box cleaning system is most effective when it serves as the final removal of residue that may have passed the primary belt cleaner on the face of the head pulley.

The Benetech Conveyor Wash Box

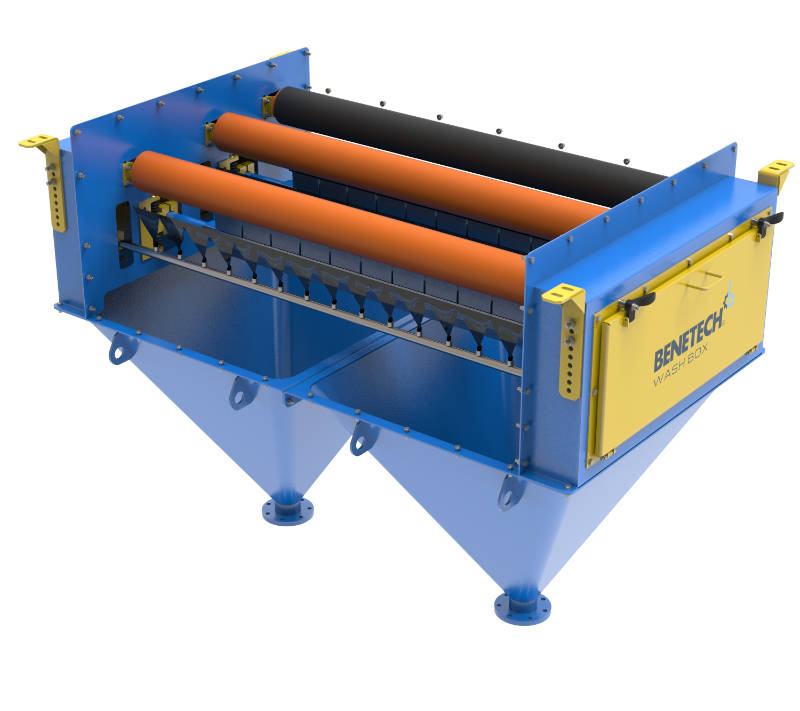

To achieve the operators’ goal of clean bulk material handling, the engineers at Benetech developed the Benetech Wash Box™. This high-efficiency secondary belt-cleaning system removes carryback and cross-contamination while supporting regulatory compliance.

To achieve the operators’ goal of clean bulk material handling, the engineers at Benetech developed the Benetech Wash Box™. This high-efficiency secondary belt-cleaning system removes carryback and cross-contamination while supporting regulatory compliance.

Built with durable stainless steel, the Benetech Wash Box is mounted on the return side of the conveyor belt. Rollers stabilize the conveyor belt while nozzles gently spray it down for cleaning by secondary scrapers when the conveyor belt enters the Wash Box. The water also helps keep the scraper blades free from build-up and extend their life by restricting thermal breakdown from frictional forces.

As the belt leaves the conveyor wash box, the rollers remove the excess water and dry the belt. The excess water and residue are then washed away and drained through the box enclosure’s discharge basins to the plant’s drainage system or a decanting basin.

The Benetech Wash Box for Conveyors

Combined with your primary conveyor belt cleaners, the Benetech Wash Box ensures thorough and compliant cleaning for your bulk material handling. Benetech customers who have installed the Wash Box note:

- a significant reduction in cross-contamination, spillage, and dust from carryback

- a decrease in housekeeping and maintenance

- an increase in the life of equipment, including conveyor belts, idlers, pulleys, and belt scrapers

- enhanced workplace safety

Benetech: Your Ally in Bulk Material Handling

Benetech stays current with your goals and concerns for running a safe, compliant, and profitable operation. If you would like to learn more about how Benetech can prevent carryback and cross-contamination in production areas, contact us at (630) 844-1300 to speak with a specialist.

Posted in Conveyor Belt Cleaners, Maintenance, and Material Handling