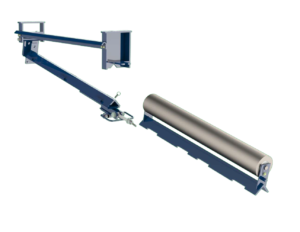

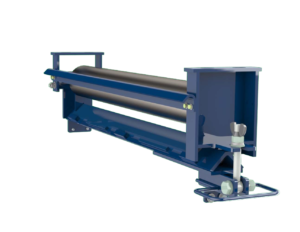

Drop & Slide Return

The Drop & Slide Return is receiving tremendous interest! Some of the reactions/comments noted most recently include:

- Cement plant on clinker belts. Dangerous area to work with slip, trip, and fall issues. Would be very helpful to service conveyors from one side only!

- Quarry tunnel under crushers. The far side wall area is too tight to work in. The big advantage to service is without having to lift a belt!

- Pet Coke refinery conveyor. Walkway one side only. Elevated conveyors are 60’ in the air. Eliminates the need for man-baskets and harnesses to work!

- Papermill transfer point area. Tight area with structural interferences. Dust everywhere. Rolling components to eliminate heat from friction on slider beds and ease of service is huge!

- Lime plant. The areas we would use them in would help tremendously with access. Time savings and ease of maintenance could really help us out. Don’t need two guys to service!

Benetech’s Drop & Slide Return Rollers allow for safe installation and removal of rollers from one side of the belt when access is restricted. In addition, the design of the frame assembly allows for placement even in confined spaces, allowing one person to change out the return roller easily and safely.

One-Sided Serviceability

One person can do service from one side of the belt.

Confined Spaces

Drop & Slide Out frame design allows quick and easy roller removal or maintenance.

Belt Support

Rollers support the belt to prevent stretching, sagging, and failure.

Easy Installation and Service

Faster installing and changing of return rollers.

Posted in Conveyor Belts