Bark and Chip Conveyor Load Zone Upgrades for Dust and Spillage Control

Situation

This southeast United States biomass plant had a severe spillage and dusting issues with their Primary Bark and Primary Chip conveyors. As a result, excessive maintenance and housekeeping surrounding conveyors affected operation efficiency greatly. In addition, concern for a safe and compliant workplace was top of mind. Benetech partnered with the plant to assess the current situation and came up with an economical solution that provided ease of maintenance, improved the material flow, and greatly reduced their fugitive dust and spillage problems at the transfer points.

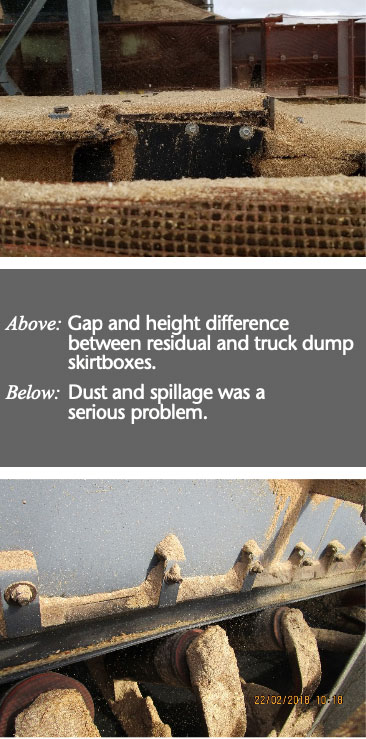

Existing Problems

The two Primary Bark and two Chip conveyors were located side by side with pant leg chutes loading material from the truck dump onto one belt and the residual material onto the other belt. The systems for the four chutes were not tied together, causing spillage and dusting between the chutes. In addition, the skirtboards did not have internal wearliners and were uneven.

The Benetech EPC Approach

Benetech provided turnkey service, such as starting with the demolition of the existing conveyor systems. Then, completing all installations within the one-week outage allotted for the project. New Primary Bark and Chip conveyor belts were engineered and installed with the MaxZone Modular Skirtboard and Belt Support System, which includes:

- MaxZone XN ® Externally Adjusted / Internal Rubber Wearliner

- High-performance dual seal B+ Apron Seals with polyurethane insert

- Quick Release Clamp Sealing System

- Peaked Hood Stilling Chambers to slow material and passively handle dust

- Simple Slide-Out Idlers for exceptional belt support and easy maintenance

- Dust-tight Inspection Doors for inspection of internal skirtboard

Successful Results

Because the upgrade’s primary driver was to reduce dust and spillage at the transfer points. And for this reason, they achieved their goal. As a result, the plant has seen a night and day difference. In addition, the upgrades created:

- Increased Safety of Workplace

- Reduction of Plant Mitigation Labor

- Decrease in Airborne Dust

- Minimize Plant Maintenance Expenditures

- Increase in Belt Life