Situation

A North American cement facility was experiencing significant dust issues due to spillage and the poor flow of its traditionally designed rock boxes chutes. In addition, because the material was not being controlled, it was causing premature wear on the belt and chute surfaces. So, Benetech partnered with the plant to assess the situation and provide an engineered solution that would control the material flow to alleviate the spillage and dusting issues. Therefore, extend belt and chute life and create a safe work environment.

Existing Problems

- High dust emissions from transfers

- Extreme spillage and material carryback

- High level of human resources required to maintain/clean system

- Premature wear of belts and chute surfaces

The Benetech Solution

Benetech provided the Engineering and Procurement of leading technology Advance Transfer Systems to improve material flow and reduce dusting. In addition, best-in-class conveyor components were used to prevent spillage and carryback. So, to ensure sustainable results, Benetech provided training for proper maintenance and upkeep.

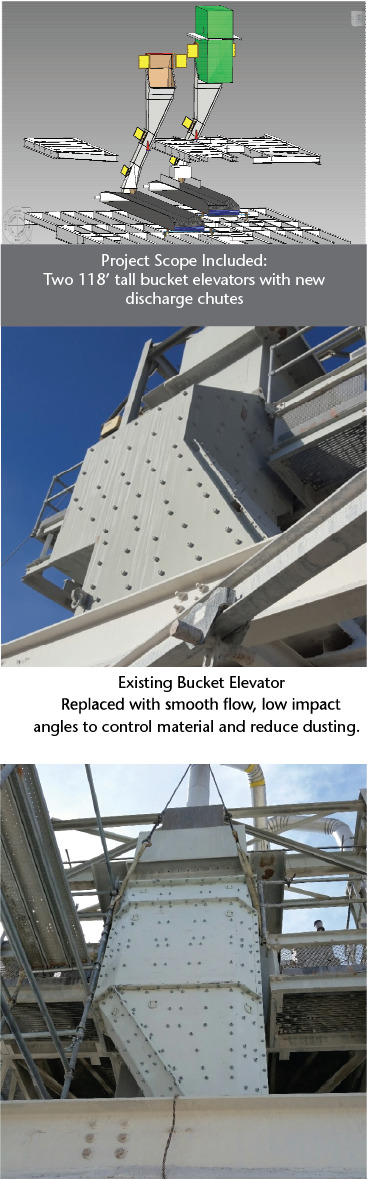

Project Scope:

Engineered Advanced Transfer Systems Replaced Existing Bucket Elevators Through Existing Conveyors

- Bucket elevator discharge opening enlarged to prevent material from dropping back into the center of bucket elevator.

- Large rock box removed.

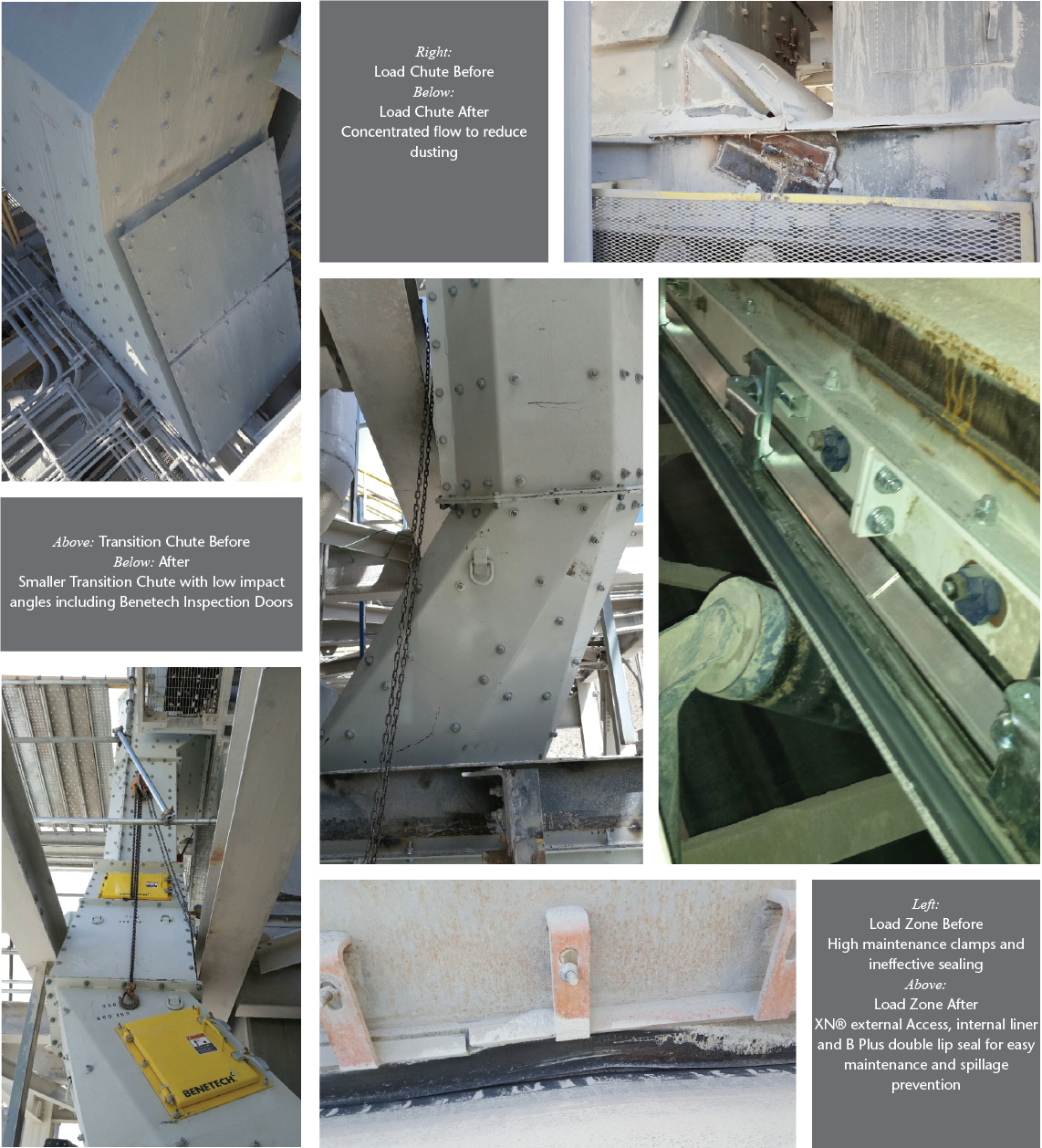

- Low impact angels added to chute design

- More minor, smoother flow chutes added

- Smooth flow, low impact angles added to the loading chute

- More concentrated flow to reduce dusting

- Smoother flow to minimize spillage

Best-In-Class Benetech Conveyor Components Utilized to Eliminate Spillage and Carryback Including:

- Patented, XN® internal liner “retrofit” assembly with B+ double lip seal

- Long-lasting, high performing belt cleaners

- Heavy-duty, easy access Inspection Doors

Training

- Benetech worked alongside facility personnel to introduce all new technologies and trained on proper maintenance techniques to ensure sustainable results.

SUCCESSFUL RESULTS

- Controlled material flow, drastically reducing dust generation

- Spillage is drastically reduced

- Increase in belt and chute life

- Reduction of plant maintenance expenditures

- Overall Safety of Operation has improved

- The ease of maintenance has improved due to XN® retrofit

- Integration of new technology with existing system minimized project capital