Coal Handling Improvements Ensuring Safety, Efficiency, & Environmental Excellence

Situation

As GNPower Mariveles Coal Plant (GMCP) started commissioning, it was evident that several systems were not operating effectively, and the plant could not operate near design. A major concern was the coal handling system, such as taking coal from the ship unloading harbor to the stockyard and the silos to feeding the units.

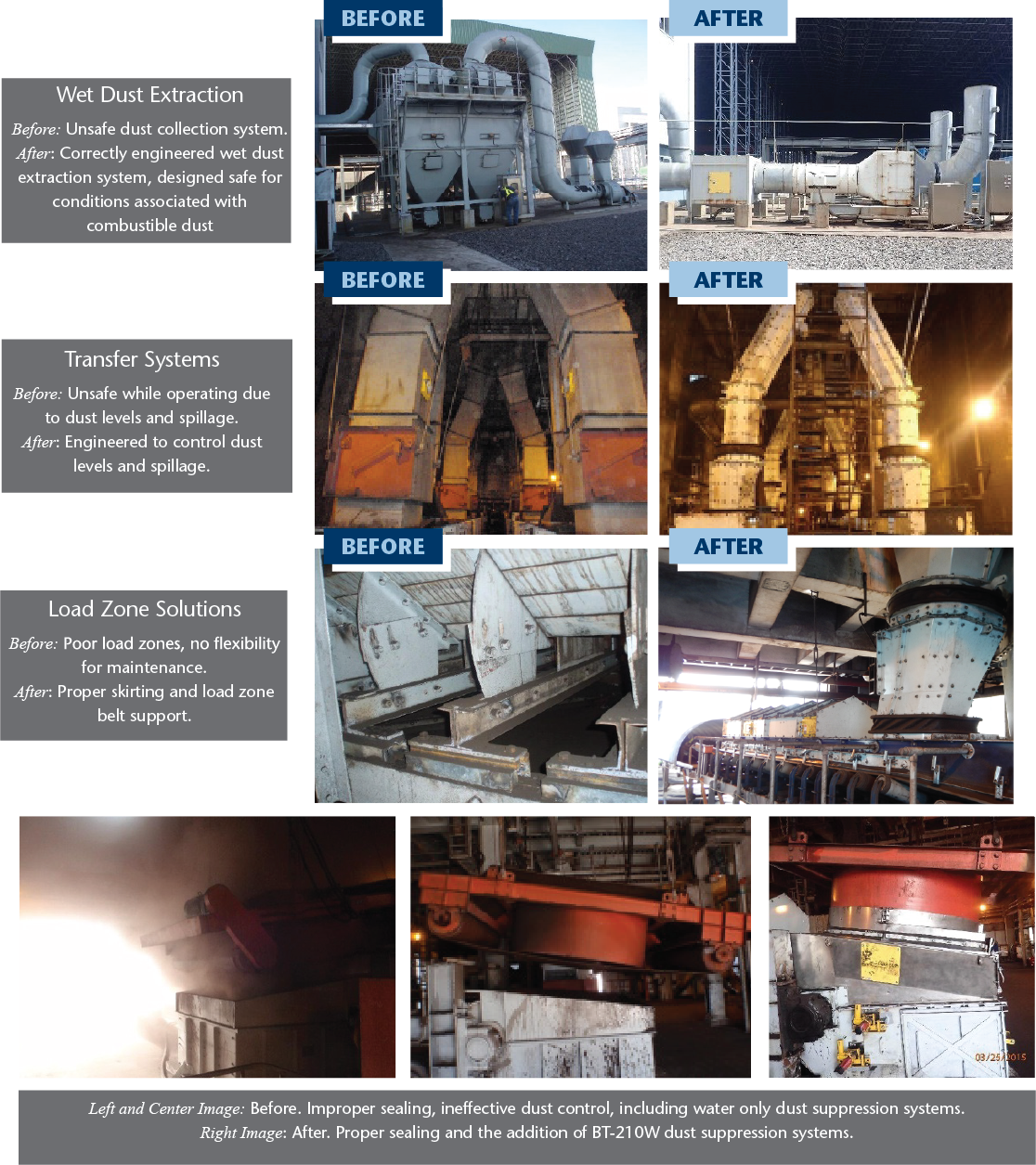

After initial attempts to address these issues with the installation contractor but not improving the situation, plant management contacted Benetech to help assess the coal handling system. Then, the direction was to review the project specifications provided to the installation contractor, evaluate the coal handling system as installed, and compare the system to the specifications required. In addition, after reviewing the specifications and detailed site inspections, a listing of non-compliant systems and components was identified. Through the support of Benetech, the plant implemented many changes to ensure efficient and safe operations, under specifications provided as part of the contract for the construction of the plant.

Benetech Technology Scope

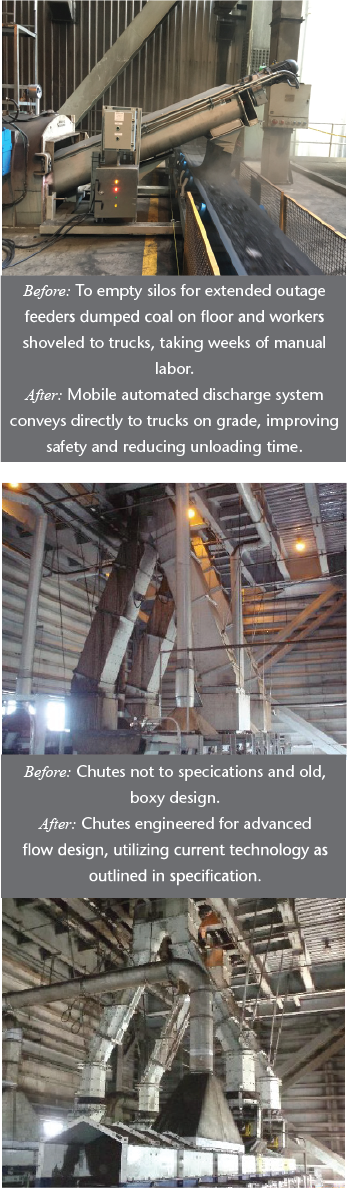

- 9 Advanced Flow Chute Upgrades

- 6 Wet Dust Extraction Systems

- 12 MaxZone Skirting Systems with Belt Support

- 4 BT210W Dust Suppression systems

- Conveyor Component replacement for all 11 conveyors

- Primary Belt Cleaners

- Secondary Belt Cleaners

- Diagonal Plows

- Engineered Belt Trackers

- Easy Access Inspection Doors

- Silo Discharge System to safely empty low CV coal from silos for the extended outage

- Engineering Support

- Structural Upgrades

- Idler Replacement

- Belting Replacement

- Conveyor Tail Rework

- Training

- Maintenance

- Safety

- Operations Support and Mentoring

Successful Results

The coal handling system upgrades included best-in-class material handling technologies that have created a safer and more efficient operation. And so, the unloading rate of a coal ship has dropped from 8 to 10 days to 3 to 4 days. In addition, the plant has seen a significant decrease in fugitive dust and spillage, resulting in lower maintenance and housekeeping hours. Most importantly, the result is a safer and healthier workplace.