Description

Lifecycle Improvements

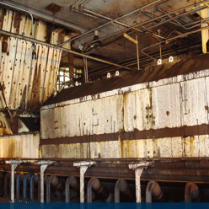

Situation

A large national utility committed resources to be invested in the handling system of one of its Texas generating stations. The goal was to ensure that it continues to perform well over its next phase of life. To handle current operations and challenges, Plant Professionals was selected as an independent resource to assess the station’s condition and help prioritize projects.

The station has multiple units, with independent rail unloading systems and material handling systems. All coal is brought in by rail from the Powder River Basin, and the plant consumes several million tons per year.

Challenges to upgrading the system included limited windows to perform the upgrades, so recommendations and designs need to consider this.

Scope

- Initial P2 assessment

- Prioritization and Plan Development, Project Management

- Benetech Technology group and partner engineer firm developed over 20 generic, technology-focused bid packages that the station used to go out to bid

- Benetech was successful on several of the upgrades and provided Project Design, Supply, Install, and management on those projects

Lifecycle Improvements Include:

- Multiple Transfer System Installations

- Redesign of Crusher system

- Washdown system

- Dust suppression System Upgrades

- Electronic Magnet

- Grizzley Project

- Scale Install

Solution Achieved

The station was able to evaluate and select several projects to improve safety and efficiency. New projects continue to move forward on the plan developed with advice and direction from the Plant Professionals team. The Benetech team continues to support the plant team in successfully implementing the lifecycle upgrades to increase safe handling of PRB coal and ensure the station is ready for the next phase of its operating life.