How Safe Is Your Stored Material?

Stockpiles are a critical component of any bulk material handling system, ensuring raw materials are redily available for continued production. Effective stockpile management involves sealing and protecting piles from moisture, improving environmental performance, supporting good-neighbor initiatives, and limiting oxygen exposure for combustible materials.

If inactive storage piles containing fuel for industrial processes are not adequately sealed:

- Materials can quickly degrade

- BTU values are reduced

- Combustion properties are modified

- Oxidation occurs

Oxidation produces an exothermic reaction, generating heat that can be accelerated by sunlight and wind. If heat continues to build, it may exceed the material’s ignition point, creating hot spots and potential combustion within the storage pile.

For non-combustible materials, improper stockpile sealing can release large amounts of fugitive dust, leading to environmental compliance issues and concerns from surrounding communities. Windblown material can also result in product loss and contamination of nearby piles, affecting downstream manufacturing processes.

Principles of Stockpile Management

While a bulk material handling operation cannot control the weather, it can minimize the risks associated with storage piles, especially those prone to dust. In addition to proper sealing, effective stockpile management strategies include:

- Considering storage pile dimensions in relation to height, wind direction, and downwind profiles

- Organizing short-term versus long-term piles

- Properly stacking materials to prevent segregation

- Compacting piles to limit air circulation

- Using thermo-imaging to monitor pile temperatures and ensure combustible materials remain below ignition points

GreenTarp: Superior Sealing of Piles and Surfaces

Benetech understands the science of efficient stockpile management. As a partner in production, we developed GreenTarp, a solution designed to keep storage piles environmentally friendly and hazard-free.

Our GreenTarp storage pile sealant combines polymeric emulsion binding agents, surfactants, and recycled cellulosic products to address challenges associated with inactive piles and ground covers. Non-toxic and non-corrosive, GreenTarp provides superior cohesion, durable water resistance, and reduced air and water ingress. Its eco-friendly formulation and distinctive green color also communicate a commitment to environmental stewardship and community relations.

The application is simple: batches are mixed onsite and sprayed using a hydroseeder. In as little as 48 hours, GreenTarp cures into a protective shell that:

- Controls fugitive dust

- Stabilizes surfaces to prevent shifting, sink failures, and material runoff/erosion

- Provides a rain-resistant, windproof barrier to minimize frozen material, oxidation, and inventory loss

- Does not pollute groundwater

- Supports regulatory compliance

Versatile Applications of GreenTarp

GreenTarp is effective for a wide range of bulk material storage and dust control applications, including:

- Coke & ore storage piles

- Mine operations

- Construction sites

- Power plants

- Fly ash sites

- Quarry operations

- Ground covers

- Soil stabilization

- Haul-road berms

- Steel mills

- Land reclamation

- Waste materials

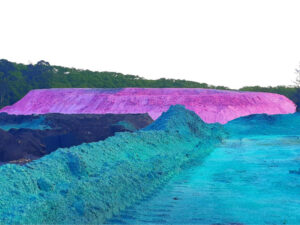

GreenTarp can also be used creatively for communication and community engagement. For example, Benetech’s Brazil operation worked with a client who used our stockpile sealant—referred to locally as GreenCarpet—for a public relations campaign. By dyeing the sealant in different colors, the client promoted various causes, including pink for breast cancer, yellow for suicide awareness, and blue for prostate cancer.

Seal Your Storage Piles the Right Way Starting Today

Correctly engineered storage pile sealant is vital to efficient operations, personal safety, and environmental protection. Find out more about how GreenTarp can take command of your stockpiles. Contact us at (630) 844-1300 today to speak with a Benetech specialist.

Posted in Dust Control, and Material Handling