Cost-Cutting Innovation in the Belt Conveyor Load Zone

Benetech MaxZone Plus

Benetech MaxZone PlusAn entirely new concept for bulk material handling, the MaxZone® Plus system acts as a modified load zone chute that keeps material flowing while reducing transfer point spillage and dust through proper center loading.

Most bulk material handlers will experience the challenge of excess spillage and dust in the load zone. This is especially true when a misaligned transfer point chute creates a flawed material transition onto the receiving belt.

Improper or off-center loading can further cause the belt to mistrack, leading to safety hazards, conveyor damage, and strain on the motor. These issues further result in material loss and extra housekeeping and maintenance in the belt conveyor load zone.

Depending on the timing of these circumstances, your business may not have the schedule or the resources for a full replacement of an engineered load zone chute, which is the best option for solving most conveyor material-flow issues. You must stay productive without a redesign and a complete change-out. How do you maintain efficiency and continue serving customers where time and budget constraints exist?

Benetech now has your answer.

Load Zone Production with Major Capital Savings and No Chute Replacement

Although these problems should be addressed, time and budget constraints do not always allow for engineered load zone chute replacement, the best option to solve most conveyor material-flow issues. To overcome this, Benetech has developed a new low-cost solution to combat off-center conveyor loading without costly chute redesign: the MaxZone® Plus system.

Benetech, Inc. has invented the patent-pending MaxZone® Plus system for a much-needed load zone solution, always attuned to your daily demands. An entirely new concept for bulk material handling, the system acts as a modified load zone chute that keeps material flowing while reducing transfer point spillage and dust through proper center loading.

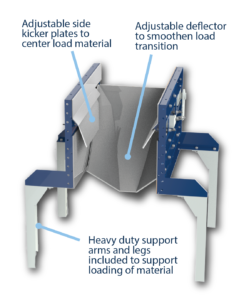

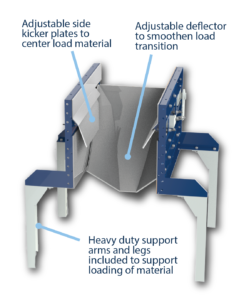

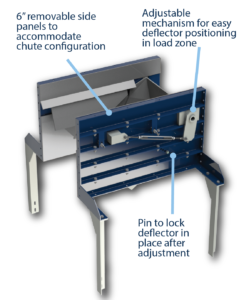

System components include adjustable side kicker plates and an adjustable deflector for smoother center loading of material onto the loading belt. In addition, removable side panels further allow height adjustment according to your belt conveyor load zone requirements.

You can also adapt the MaxZone® Plus system to existing Benetech XN Wear Liners and retrofit it to other containment systems. You have access to different liner options as well.

Combined with the MaxZone® Modular Skirtboard and Conveyor Belt system, the MaxZone® Plus achieves the results you require at a much lower cost than other solutions. Because the system often eliminates the need for an engineered transfer point chute, your business can cut capital expenses by more than $200,000.

The distinctive design of the MaxZone® Plus can also save your plant tens of thousands in clean-up expenses while reinforcing safety compliance. Furthermore, in step with current health and safety concerns, the system needs only one person for maintenance, allowing for proper social distancing if mandated by plant policy. The MaxZone® Plus can be installed easily into an existing Benetech MaxZone® and retrofitted to other containment systems.

Stop Transfer Point Spillage, Enhance Material Flow

We understand how important it is to have versatile options in the belt conveyor load zone. However, we also know time and expense are of the essence. The MaxZone® Plus system is just one more way we support your mission of greater profits and service with lower risk and maintenance. We will provide the ultimate belt support and solutions for your load zone with our MaxZone® Modular Skirtboard and Belt Support System and MaxZone® Plus. Contact us at (630) 844-1300 to speak with a Benetech specialist.

Posted in Conveyor Belts, and Material Handling