If compliance is a concern at your plant, Benetech has your efficient solution.

The Benetech Wash Box is a secondary conveyor belt–cleaning system for eliminating any carryback that remains on the belt. The Wash Box is ideal for systems conveying material that is hard to remove with typical belt-cleaning systems.

The conveyor wash box is equally effective with belt-surface blemishes that trap material. Trapped material passes under both primary and secondary cleaners and, after later dislodging, can create dust and spillage problems. Using water for belt-cleaning softens the trapped material so it can be properly removed and discarded.

The belt wash box is mounted on the return side of the belt, where secondary cleaners are typically placed. When the conveyor belt enters the enclosed box, rollers stabilize it while the nozzles gently spray it down and secondary scrapers clean it.

As the belt leaves the conveyor wash box, the rollers remove the excess water and dry the belt. The excess water and residue are then washed away and drained through the enclosure’s discharge basins to the plant’s drainage system or a decanting basin.

Combined with your primary cleaners, the Benetech Wash Box ensures complete, compliant cleaning for your application or material.

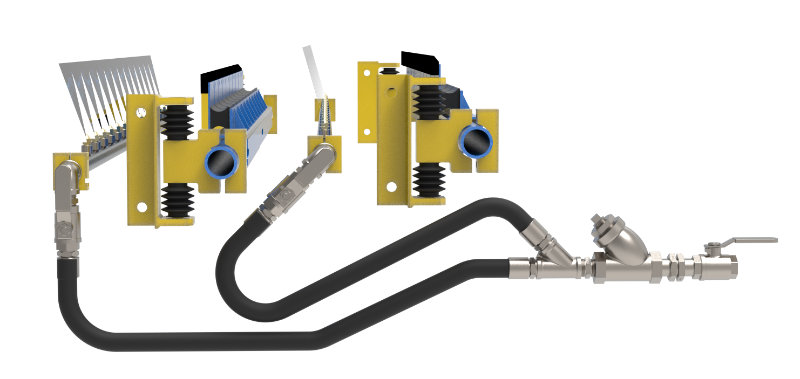

![Benetech Wash Box]() Benetech Conveyor Belt Wash Box Components

Benetech Conveyor Belt Wash Box Components

Benetech’s conveyor belt wash system includes the following to achieve a cleaner, safer, and more efficient production for your bulk material handling.

Spray Nozzle Bars

Spray nozzles moisten the carryback for much easier removal of residue from the belt by the scrapers. The spray bars are sized to suit the width of your belt.

| Belt width (inches) | 36″ | 42″ | 48″ | 54″ | 60″ | 72″ | 84″ | 96″ |

|---|---|---|---|---|---|---|---|---|

| Nozzles per manifold | 7 | 8 | 9 | 11 | 12 | 13 | 15 | 16 |

| Manifold on wash box | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Total nozzles | 14 | 16 | 18 | 22 | 24 | 26 | 30 | 32 |

| Total flow (liter/minute) | 54,6 | 62,4 | 70,2 | 85,8 | 93,6 | 101,4 | 117 | 124,8 |

| Pressure (bar) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Rollers

Four conveyor wash box rollers help support and stabilize the conveyor as it moves through the enclosure while removing the water and drying the belt as it exits.

Secondary Belt Cleaners

Two sets of Benetech’s secondary cleaners guarantee the most efficient system performance.

![Wash Box parts]() Enclosed Piping

Enclosed Piping

The feed-distribution system to manifolds is equipped with a maintenance valve and filter to remove any impurities.

Inspection Doors

Benetech installs your belt wash box with two of our heavy-duty, dust-tight Inspection Doors. The doors’ distinctive design provides safe and easy access for performing preventative maintenance. The Inspection Doors also features a deflector panel, grease fittings on pinned hinges, tough door seals, never-seize latches, and heavy-duty handles.

Discharge Basin

The generated effluent drains safely through the discharge basin and is directed to the plant’s drainage system or a decanting basin.

Wash Box Literature

| Wash Box - Flyer | Download |

| Wash Box Installation - Manual | Download |

Benetech Wash Box: Find Out More Today

Benetech puts the best of our engineering, design, and technology to solve your production challenges and help keep you in compliance. Discover even more about how our conveyor belt wash box can improve your daily operations. Contact us at (630) 844-1300 to speak with a Benetech specialist.

Benetech Conveyor Belt Wash Box Components

Benetech Conveyor Belt Wash Box Components Enclosed Piping

Enclosed Piping