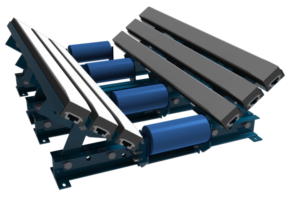

Benetech Idler Types

Idlers, Return Idlers, Training Idlers, and Impact Beds

Benetech is a global leader in comprehensive, performance-based bulk material handling solutions. Our complete solutions toolbox address a wide range of issues in the bulk material handling systems at the surface and underground mines, coal-fired electric generating plants, refineries, steel mills, pulp and paper mills, biomass facilities, cement plants, coal trans-loading facilities, aggregate, and stone operation. These conveyor belt idlers exceed CEMA standard load ratings, are available with standard or wide base frames, come in any belt width and troughing angle, and utilize impact or steel rolls.

Features

• Available with standard or wide base frames

• Comes in any belt width and troughing angle

• Utilizes impact or steel rolls

• CEMA classes: B, C, D, and E

PARTS / DESIGN |  |

Light-Weight Welded Head | |

Heavy / No Weld Pressed Head | |

Bearing: 6204 | |

Bearing: 6304 | |

Double Labyrinth Seal | |

Triple Labyrinth Seal | |

Contact Seal Part of External Cap | |

Contact Seal Not Part of External Cap | |

Shaft Type: 1018 | |

Shaft Type: 1045 | |

Snap Ring: Locks Bearing & Seals | |

Tapered Head Design | |

Flat Head Design |

Benetech Idler Types

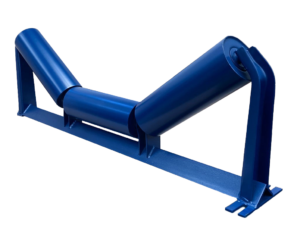

Fixed Frame Troughing Idlers – Standard or Impact

Benetech’s troughing idlers are used to transition from an impact area or load zone. They can also transition from a flat pulley area to a picking or feeding area. They meet all CEMA requirements and are available in standard or impact, belt widths 24-72″, and troughing angles of 20, 35, & 45 degrees.

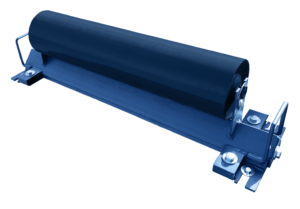

Standard Returns – CEMA B, C, D, & E

Benetech’s standard returns are used to carry the belt back to the tail pulley after the load has been dumped at the head pulley. Designed to meet CEMA standards and available in different belt widths.

Simple Slide Idlers

Roller frames slide into place without the need to remove adjacent idlers, resulting in excellent serviceability and improved safety. In addition, the compact size of the frames allows for placement even in confined spaces, assuring that you are getting the belt support you need.

Simple Slide Flat Carrying Idlers

Benetech’s Simple Slide Return Rollers allow for safe and simple installation and maintenance while providing optimal belt support between the discharge point and the tail pulley. In addition, the compact size of the frames allows for placement even in confined spaces.

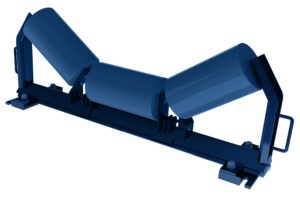

Drop & Slide Idlers

Benetech’s patented Drop & Slide Idlers (Patent #11919719) incorporate a retractable side support roller unit that is designed to provide access from a conveyor’s serviceable side. The unique design of this idler allows it to be installed where one side of the conveyor system may have very limited or no access thus preventing normal idler maintenance.

Reversible Return MaxTrackers

The Reversible Return MaxTracker responds instantly to the misalignment of the belt without special modifications to the structure. It requires no maintenance and fits into a standard drop bracket. The Training Idler can be manufactured to suit all belt sizes in operation.

![]()

Troughing MaxTrackers

The unique design of the components of the Troughing MaxTracker training idler frame allows it to automatically adjust itself to the conveyor belt to correct the misalignment in the troughing section of the conveyor, keeping your conveyor belt on track.

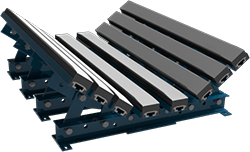

Warrior Impact Bed

The Warrior Impact Bed stabilizes and supports the conveyor belt during loading. Rubber bars of the Warrior cushion the belt and absorb impact resulting in longer belt life, eliminating spillage, and decreased O&M costs. In addition, the durable frame of steel supports impact on the bars.

Warrior Roll & Guide

The Warrior Roll & Guide Support bed creates a seamless seal, helping to eliminate dust and spillage in the load zone. In addition, it utilizes low friction slider bars on the wing sections and rollers in the center. As a result, belt drag is minimized while the belt is fully supported at the edges.

Benetech Idlers Features & Benefits

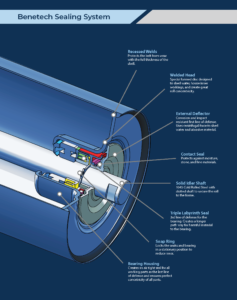

Benetech Sealing System

Benetech’s labyrinth sealing system protects the roller from all types of contaminants found in polluted or corrosive environments, such as washdown areas, fine dust, and debris. The sealing system consists of a vertical triple labyrinth seal protecting against dust, a male and female labyrinth seal protecting against water and moisture, and a metal seal against material with particle size greater than .0625in. This combination of multiple seal designs will maintain and extend the life of the roller against abrasive material.

- Recessed Welds – Protects the belt from wear with the full thickness of the shell.

- Welded Head – Specially formed disc designed to shed water, house inner workings, and create great roller concentricity.

- External Deflector – Corrosion and impact-resistant first line of defense. Uses centrifugal force to shed water and abrasive material.

- Contact Seal – Protects against moisture, stone, and fine materials.

- Solid Idler Shaft – Manufactured with 1045 cold-rolled steel and slotted shaft to secure roller to the frame.

- Triple Labyrinth Seal – Third line of defense for the bearing. Creates a longer path way for harmful material to the bearing.

- Snap Ring – Locks the seals and bearing in a stationary position to reduce wear.

- Bearing Housing – As the last line of defense, the housing creates an air-tight seal for all working parts and ensures perfect concentricity of all parts..

Benetech Idlers Features & Benefits

Rollers

The outer and inner body of the roller and the lateral metal covers provide a completely sealed and rigid capsule. During the operational life of the roller, this unique assembly design guarantees the optimal performance of the shaft, bearings, and sealing system.

Housing

The inner body or bearing chamber is a complete piece inside the roller. Its purpose is to guard all of the inner components of the roller out to the head. Unlike other rollers on the market with independent bearing chambers, the main advantage of our design is that perfect concentricity is achieved, therefore prolonging the roller life.

Bearings

Benetech rollers come with top-of-the-line 2RS ball bearings. Due to the construction of these bearings, they provide adequate resistance to radial and axial loads. As a result, the 2RS bearings promote high-level performance and require no maintenance or regreasing during their lifetime.

Welding

Benetech uses robotic Metal Inert Gas (MIG) welding to construct the roller head. With this technology, the weld is more resistant to cracks or breaks. Since flux is not used, there is no chance of slag entrapment, resulting in a clean quality weld. In addition, the MIG weld improves the finish and resistance to normal wear, increasing the lifetime of the roller.

Shafts

Consistently exceeding CEMA standard load ratings, the idler shaft size will be different depending on CEMA class. The roller shafts are manufactured with top-quality grade steel.

Idler Videos

The Benetech MaxZone® product line is designed to reduce maintenance time and cost while maximizing material throughput, system uptime, and safety for plant personnel.

Things to be aware of:

There are many different sizes and types of idlers made by multiple manufacturers, so you must order the correct size and style to minimize problems in the conveying system. Incorrect idler sizing or specification can lead to belt damage, cargo spillage, premature equipment failure, or even more catastrophic events. Therefore, take care while ordering and using the correct size frames and idlers in a conveying system. In some cases, the materials used in the construction of the idler frames or idler rolls may not be compatible with the material being handled, and contamination of the conveyed product can occur.

Conveyor Components Literature

| Products & Services - Catalog | Download |

| Products & Services - Line Card | Download |

| Idlers - Catalog | Download |

| Idlers - Line Card | Download |