Pet Coke Transfer Point Suppression Treatment For Stackout/Storage

Situation

The Pascagoula Refinery ships out petroleum coke to many parts of the world and is located directly on the Gulf of Mexico at the mouth of the Pascagoula River. The size and consistency of the pet coke range from very fine to small pellet size. The refinery was experiencing dusting problems during stack out, off of its storage piles, and then during ship loading. They turned to Benetech to find a solution.

The Benetech Solution

Benetech assessed the situation and determined that an application at one location would resolve their issues. Therefore, a system was installed to

perform a complete body treatment as the pet coke is transferred from the refinery to the storage yard. The product used to treat the pet coke is GDS-12, applied at 1% moisture or 2.4 GPT.

Successful Results

The system at Chevron Pascagoula is very effective, and the refinery is satisfied with its performance. The additional moisture has resulted in no adverse effects. One treatment point is effective during stackout and to control the pile when the coal is stored. During dry weather, the solution has lasted up to a month. Any rain “reawakens” the solutions and provides even more extended protection on the storage pile. In addition, the treatment is very successful in reducing dusting as the pet coke is loaded from the storage yard onto outgoing ships.

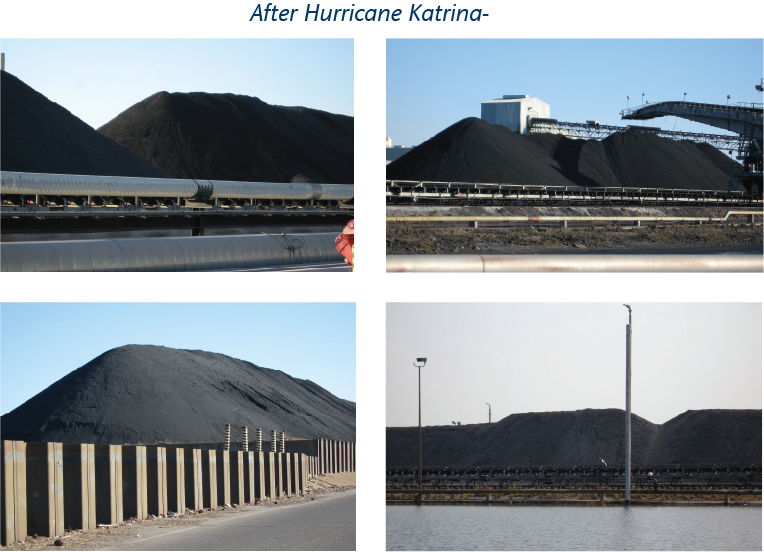

Hurricane Katrina

In 2005, the refinery was hit by the most devastating Atlantic tropical cyclone of the season. Images below, taken shortly after the hurricane, show that the pet coke piles stayed in place. However, the lower 8′ of the pile was submerged underwater, and the upper portion was hit by 150 mph wind and rain. The Benetech Solution was successful in protecting the storage piles from very costly destruction.