Bulk material handling professionals know the problems that can arise with the conveyor belt. A belt that isn’t properly moving can disrupt your operation’s entire schedule. Mistracking, belt slipping, and material blockage and spillage can halt production and result in costly maintenance. This becomes especially true in harsh environments.

Having proper conveyor belt idlers is vital to the conveyor belt’s performance. By supporting the belt and the material being conveyed, conveyor idlers help prevent the belt from tearing, stretching, and sagging – and ultimately failing. In this way, they help to maintain and prolong efficient production while also extending the life of the belt.

At the same time, changing conveyor belt idlers can become problematic one side of the conveyor does not allow access. If access on that side is restricted, changing out the rollers often cuts into production time and might even create safety issues for personnel.

If your plant contends with access limitations when exchanging conveyor idlers, you might wonder if a safer, more efficient solution is available. The answer is yes.

The Drop & Slide Idler: Safe, Quick, Easy, High-Performing

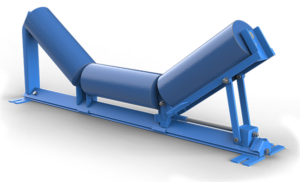

The Benetech Drop & Slide Idler reduces maintenance expense and labor while maximizing material throughput, system uptime, and employee safety.

The Benetech Drop & Slide Idler reduces maintenance expense and labor while maximizing material throughput, system uptime, and employee safety.

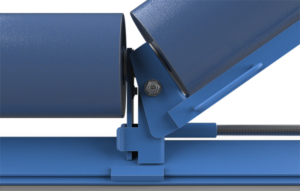

It achieves these vital objectives with a design that adapts to the challenge. A retractable, side-support roller unit allows the servicing and replacement of conveyor idler rollers when access to an idler assembly is limited, blocked, or unsafe.

When in the retracted position, the roller unit simply slides out from under the existing conveyor belt. The Drop & Slide Idler assembly can be fully dismantled, inspected, and serviced by one person from one side of the conveyor.

Installing the Drop & Slide Idler is easy as well – no need to raise the conveyor belt or remove adjacent idlers. The idler is most commonly placed in transfer point or load zone areas, but it can be used anywhere on the carrying side of the belt.

The Drop & Slide Idler meets CEMA Class C, D, and E standards. You can acquire the conveyor belt idler as either impact or steel rolls in any belt width and troughing angle. The conveyor idler also is available with both standard- and wide-base frames and is compatible with any matching Benetech Simple Slide Idler frame.

Conveyor Idler Solutions That You Need and Expect

The Drop & Slide Idler joins the Simple Slide Idler as another way Benetech’s engineers remain alert to the factors that mean the most to your production, safety, and profitability.

If access to a side of the conveyor belt isn’t blocked or restricted, the Simple Slide Idler’s roller frames slide right into place without having to raise the belt or remove adjacent idlers, even in tighter spaces.

Also, like the Drop & Slide Idler, the Simple Slide Idler comes in any belt width or troughing angle and is available with standard- or wide-base frames. The idler can use impact or steel rolls as well. The result once again is easy, safe, and efficient maintenance that supports greater production and conveyor-belt life.

Benetech Conveyor Idlers: Find Out More Today

While you stay busy handling bulk material, Benetech stays busy developing solutions and services that help you achieve your plant’s greatest potential. If you have a challenge with access to a side of the conveyor belt for maintenance, let’s discuss how the Drop & Slide Idler can provide your solution. Contact us at info@benetechusa.com to speak with a Benetech specialist.

Posted in Conveyor Belts