Material handling systems involve the constant movement of massive amounts of product along the conveyor belt, the heart of production. With so much size, weight, and machinery in motion, personal safety in the load zone remains an ever-present concern.

Just a few hazards related to conveyor equipment and components are:

- material spillage that falls or is ejected from the conveyor

- respirable and combustible airborne dust

- lack of guarding or safety equipment around components traveling at high speeds

- worn or seized components causing friction against the belt

Accidents at a facility can range from minor to fatal. According to the U.S. Department of Labor, conveyors cause more than 50 workplace fatalities each year. Beyond great personal loss, an injury or death involving a conveyor belt can result in legal problems, worker’s comp and other liabilities, and lost production time.

An operation that is conscientious about its employees – and, by extension, its compliance, productivity, and customer service – will make workplace safety a leading objective. Conveyor safety also supports longer equipment life.

What Are Good Conveyor Safety Tips?

Operators can reinforce conveyor safety in the workplace by identifying possible hazards as well as how to prevent and avoid them. The following are a just few practices that can be followed.

Properly train personnel. Only individuals who are trained to operate conveyor equipment should be allowed to control it. Personnel should know where emergency stop switches or pull cords are located and how and when to use them as well.

Workers also should never climb, step, sit, stand, or ride on a moving conveyor belt, nor should they reach into or underneath it when it is in motion.

Management should provide regular updates and refresher courses to ensure that staff are current with the latest conveyor safety information. If customers or other guests visit the plant, they should be informed of the facility’s efforts to ensure conveyor belt safety.

- Install correct safety equipment. A material handling system should include only approved conveyor guarding. Dangerous moving parts should not be exposed. If the conveyor belt is an overhead system, all guards must be in place.

- Do not misuse or modify conveyor controls. Unqualified personnel should never try to change, disconnect, or otherwise misuse conveyor controls. The controls belong to a large, connected system, and incorrectly altering them can create a hazard. Any modifications should be approved by management and made only by qualified staff.

- Practice proper belt awareness and proximity. Personnel should be clear of the conveyor belt before it starts up. They should know it is about to be switched on, and the system should have a highly visible and audible alert that it active.

- Wear safe clothing. Employees working in the load zone should wear hard hats and proper shoes and not wear loose items or clothing. An operation might also adopt a policy of checking personnel for proper attire before they work near the conveyor.

- Make reporting easy. The operation should have a reporting system that makes it easy and comfortable for personnel to bring a safety concern to management’s attention.

- Keep to a maintenance schedule. Beyond impeding production, worn or defective conveyor components can become dangerous. Regular inspection and maintenance reinforce proper conveyor belt operation and safety. Belt tracking, seized idlers, and all other operational components should be checked before the start of each shift. The conveyor belt also should be serviced or repaired only after proper lockout-tagout procedures have been followed.

Benetech provides site-specific or in-house material handling training classes that focus on an operation’s specific safety and maintenance requirements. During the classes, plant personnel learn how they can make their work environment safer while also contributing to greater productivity and profitability.

Conveyor Safety in the Workplace: Equipment Inspections

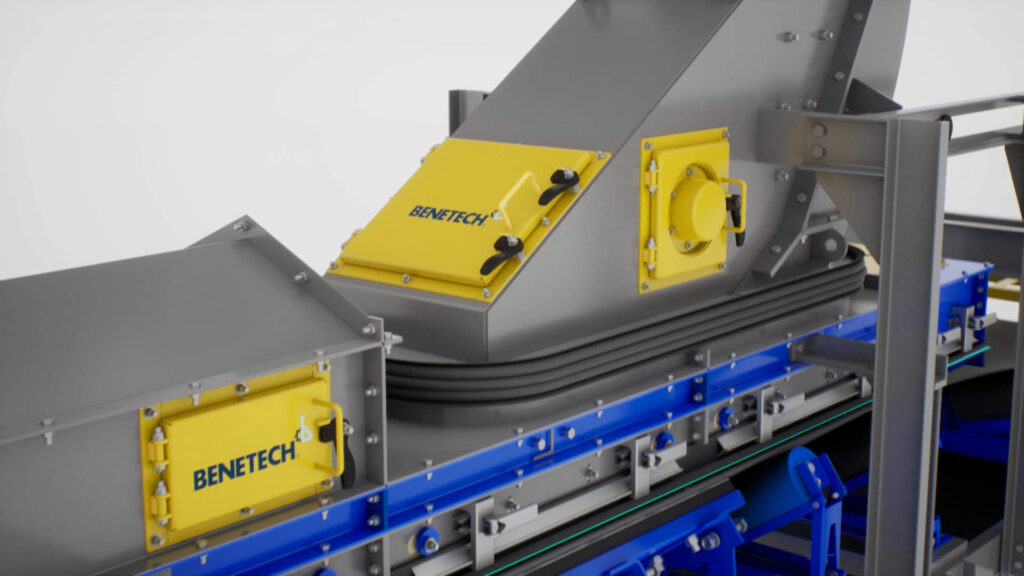

A major asset to load zone and conveyor belt safety is being able to safely examine conveyor equipment. An inspection door allows safe access to equipment inspection, cleaning, and maintenance.

Dust-tight and made of mild or stainless steel, a good inspection door will include features such as:

- dust-tight seal that stops material from escaping the inspection hatch

- door-deflector panel that deflects abrasive material during the material flow

- greased fitting on pinned hinges for no play or locking up

- resilient door seals hidden in the groove for long-lasting service

- ergonomic cam-action and never-seize closing latches with adjustable tension for suite operation requirements

- heavy-duty handles that don’t bend

- different available sizes, including custom sizes

- easy installation with a simple cut-and-weld or bolt-on process

- a protection screen for inspection while equipment is running

The inspection door also will allow inspection in tight spaces, work in a wide range of temperatures, and withstand applications with positive or negative pressures.

When personnel can safely and easily observe and inspect conveyor equipment, industrial safety becomes much simpler to manage. Needed repairs and maintenance can be completed more often and much faster, leading to greater performance and uptime of conveyor components.

What Is Conveyor Belt Containment?

Bulk material handling can generate large amounts of loose product that if not controlled can lead to safety, health, and mechanical problems. Conveyor belt containment involves keeping material flow–generated dust from becoming airborne and eliminating material spillage to provide a safer working environment. Components supporting the load zone containment systems are warrior impact beds, roll and guide impact beds, and impact idlers.

One particular problem can be carryback, the dust and small particles that cling to the conveyor belt, causing belt mistracking and excess belt damage, which decreases component and belt life. Because carryback creates extra spillage and dust, more downtime, housekeeping, and equipment wear typically result. In addition to the conveyor belt, other trouble spots for spillage and dust are often the skirting seal and poor transfer chute design.

To mitigate sources of spillage and dust, a good conveyor belt containment system will ensure proper material transfer in load zones and provide correct skirtboard sealing. This will help prevent product and dust from escaping and keep it in the material flow.

Other common features of effective conveyor belt containment include properly sized chutes, an abrasion-resistant wear plate (e.g. ceramic or steel), enclosed skirting, and conveyor belt scrapers.

The system should suit the conveyor belt’s width and speed, need minimal downtime for installation, and require no welding or hot work. Change-outs will be easy as well.

Benetech: Your Ally in Bulk Material Handling

Benetech supports conveyor safety at your workplace with the equipment, components, and training for effective compliance. If you would like to discuss our solutions for industrial safety, contact us at (630) 844-1300 to speak with a specialist.

Posted in Conveyor Belts, and Material Handling