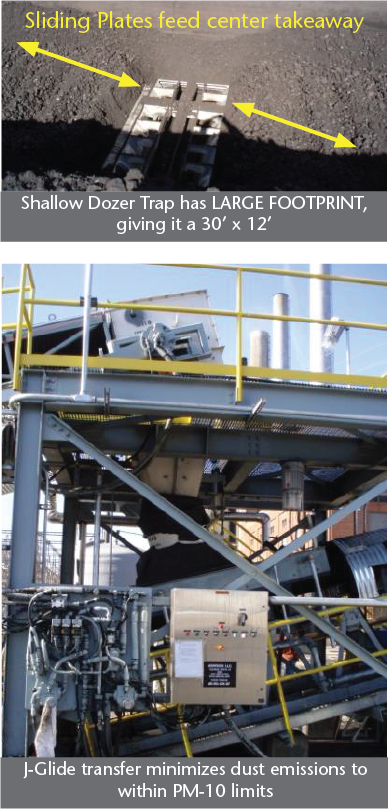

Ameren Hutsonville Adds Safe+ Shallow Dozer Trap Coal Reclaim System

Situation

Originally built over 50 years ago for high sulfur fuels, the coal yard was currently needing high ongoing maintenance. In addition, significant upgrades, both mechanical and electrical, were required to comply with both current codes and corporate safety mandates for handling and burning PRB coals.

Benetech Advantage

The plant was looking for NEW value-added ideas that would incorporate cutting-edge technologies at an affordable cost. By developing/utilizing new unloader technology and effective transfer chutes, Benetech was able to provide a solution that fits within the budget of Ameren( bringing the project back from the shelf) and met all objectives. In addition, Benetech works well in situations where TEAMING with the customer brings more dialog and success.

Driving Objective and Results Achieved

Objective: PRB Coal Safe System

Results: Utilized PRB Best Practices (significant input from Benetech). Electrical MCC is located remotely from System. Reclaim machine design unfolds upward for maintenance and cleaning purposes. The shallow reclaim vault has NO tunnel with no skirtboards required. Transfer Systems utilize dust mitigation techniques with no harboring of fines. Valve activated wash down system included within the vault along with a slight grade for easy drainage.

Objective: Cost-effective solution (capital and O&M costs)

Results: With less infrastructure modification required, creating a 200% lower cost project savings. This was due to eliminating several conveyors and a new Shallow Dozer Trap, certified for use through a partnered approach for developing design, supply, and construct.

Objective: Replaced aged coal yard to reduce Risk Index

Results: Elimination of all but one pre-existing conveyor system. Abandoning five existing conveyors, including two transfer houses (one crusher) and one lengthy reclaim tunnel. Reduce transfer points from five to three (including reclaim and crusher) to achieve the same objective. Antiquated MCC was also replaced as part of this project.

Objective: Minimize outage requirements for cut-over

Results: All work performed during non-fueling periods. Requiring the minimal out during the cut-over period due to careful planning and coordination.