Coal Handling Improvements: Minimizing Environmental Footprint

Situation

In a process to ensure GHECO ONE performs as safely and efficiently as possible while minimizing its footprint on the environment, Glow Energy committed resources to invest in the material handling systems. Initially, the operational focus of the plant was boiler efficiency. However, with the combustion systems working well, it was time to focus on coal handling. So, Benetech was chosen to assess the condition of the station and help in the prioritization of projects to make sure the best industry practices were in place and fully understand the current operations and challenges.

- No conveying redundancy

- Difficulty in meeting design capacities

- Wet coal during monsoon season

- Excessive spillage and dust result in high housekeeping and maintenance costs.

- Mind-set challenge-doing the right thing the way it has been done vs. understanding new methods and improved technologies.

Scope For Assessment

Coal handling challenges addressed:

- Dust Control

- Spillage

- Operating Efficiencies

- Employee Safety

- Protection of Owner Assets and Investments

Benetech Technology Scope

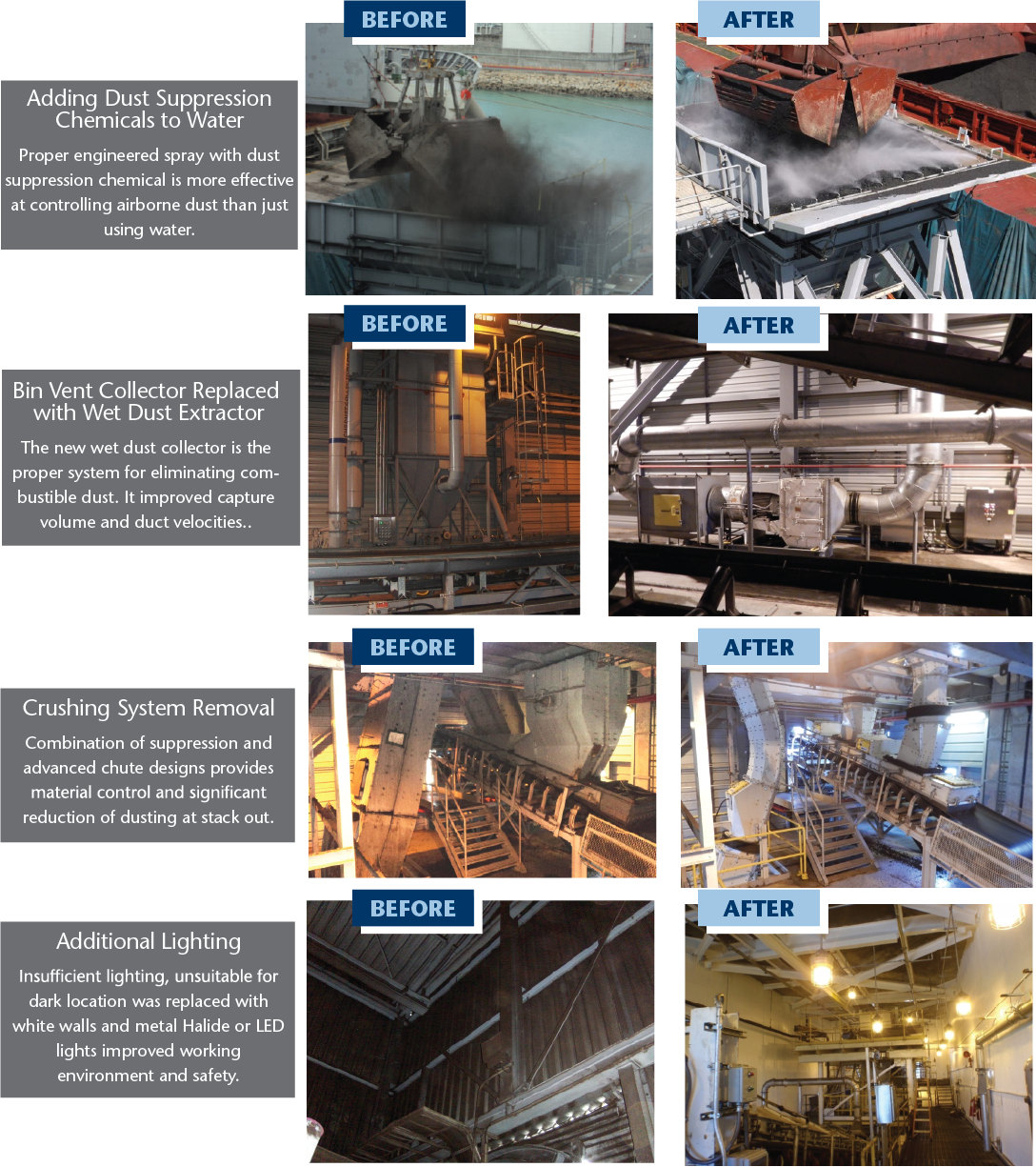

The assessment report outlined many opportunities to improve the safety and efficiency of the operation. In addition, estimated costs associated with each project were included. These findings are used to evaluate and prioritize upgrade implementation. Benetech was awarded the design, supply, and supervision for many of the upgrades, including:

- Plant Personnel Training

- 3 MaxZone Modular Skirtboard and Belt Support Systems

- 2 Advance Flow Chutes with three additional MaxZone Systems

- 2 Wet Dust Collection Systems

- Ship Hopper/Feeder Dust Suppression Systems

- Reclaim Dust Suppression System

- Transfer Building Dust Suppression System

- Complete replacement of Cleaners and Belt Plows

- Inspection Doors for safe and easy access

- Replacement of existing Belt Trainers and Return Idlers

Successful Results

- Spillage and Dust accumulation was reduced by 66%

- Unplanned Cleaner Man-hours reduced by 85%

- Planned Cleaner Man hours reduced by 81%

- Water Usage was decreased by 30%

- Housekeeping Labor hours reduced by 50%

- Bunkering time associated with fueling during Monsoon season reduced by 34%