Situation

With the implementation of Maryland’s Clean Air Act, Constellation Energy needed to evaluate options to meet emissions regulations for future operations at their coal-fired plant, CP Crane. To assist in this evaluation, Constellation contracted Benetech’s Plant Professionals division to conduct initial studies for the feasibility of utilizing sub-bituminous fuel in the handling systems. Although substantial modifications to the existing systems would be necessary, the initial study showed possible. The P2 report outlined the major changes that were necessary to achieve a safe and

efficient operating environment, as well as the estimated costs that would be associated.

Benetech Advantage

The plant was looking to make major modifications to burn sub-bituminous PRB coal, and they needed a company they could trust. With best-in-class technologies and superior industry knowledge, Benetech provided a solution that fits within the budget of Constellation and met all objectives. In addition, Benetech’s extensive PRB knowledge and ability to TEAM with the customer brought important dialog and ultimately assured success.

Driving Objectives and Results Achieved

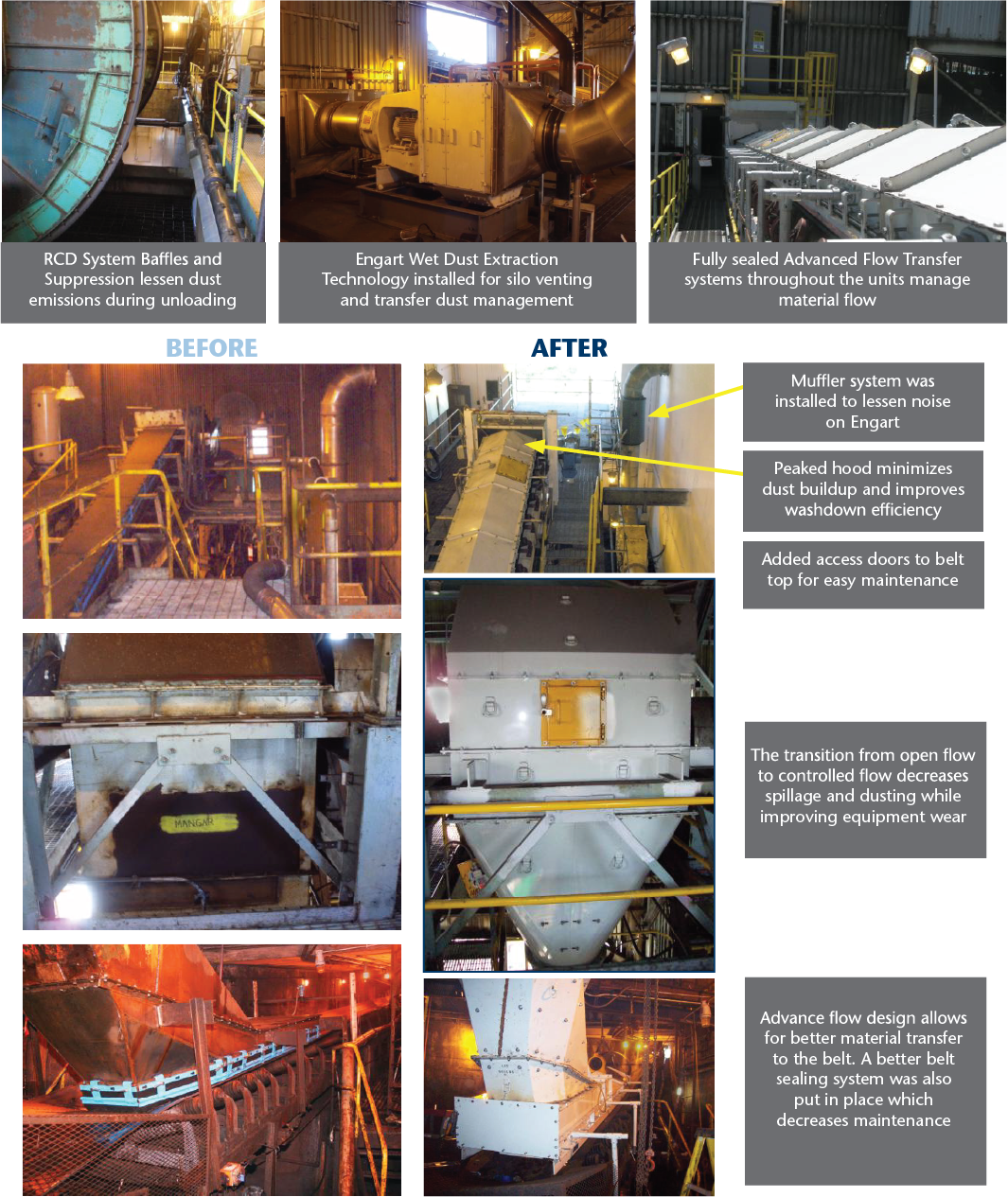

- Convert operations from bituminous to sub-bituminous material

- Increase system capacity by 100%

- Decrease noise and dust generation to address neighborhood issues

- Improve coal handling operations to automate system controls

- Improve coal handling operations sufficiently to meet/exceed

- Maryland’s Clean Air Act requirements

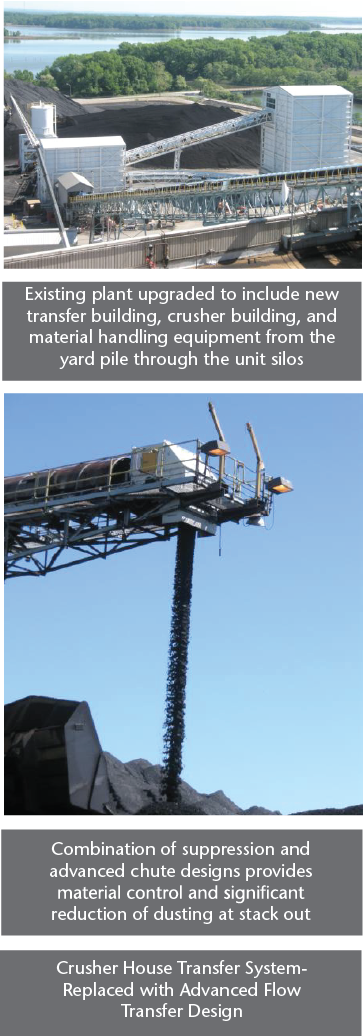

- Design, fabricate and install all equipment in new crusher and transfer buildings to allow usage of new Pennsylvania Crushers.

Driving Objectives and Results Achieved

- Nine Transfer systems, including Advanced Engineered

- Chutes and InteliFlo® Transfer Systems

- Equipment upgrades to RCD area including vibratory feed chute and dust suppression baffle system

- Benetech installed two wet dust collection systems in the transfer and crusher area.

- Five-point dust suppression system in crusher area

- Modification of existing multi foam point in the new transfer area

- Installation of Benepak Fly ash chemical injection system

- Train Constellation Operations in the running with PRB coal