Fixed Automated Washdown System For Safer Operations

Situation

A 500 MW Coal-Fired Power Plant, located in the Midwestern USA experienced a dangerous explosion due to combustible dust. The coal handling department had been in the process of dumping 57 coal cars to the coal bunkers, storing them out to the storage pile, and blending in medium-sulfur coal the day the explosion occurred. The belief is a cloud of dust provided the fuel for the explosion. The impact of the tensioning weight hitting the floor or by the belt’s violent movement at separation created the dust cloud. The dust filled the take-up enclosure and exploded when it reached its ignition source. Fortunately, the explosion caused no injuries, and due to the efforts of firefighters and plant staff, the fire never entered the plant despite traveling up the take-up enclosure. However, this event led to the plant implementing new protocols, procedures, and equipment to prevent similar incidents from occurring again. Amongst the variety of new equipment added was the installation of an automatic washdown system.

The Benetech Solution

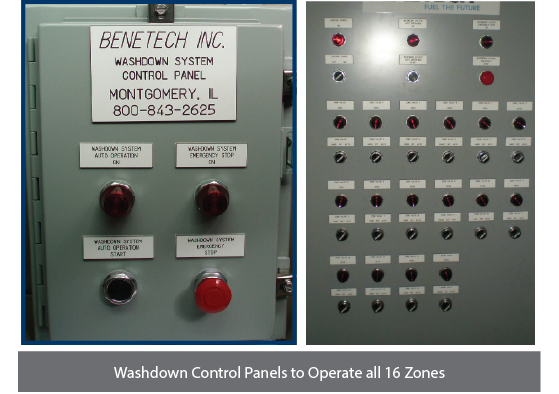

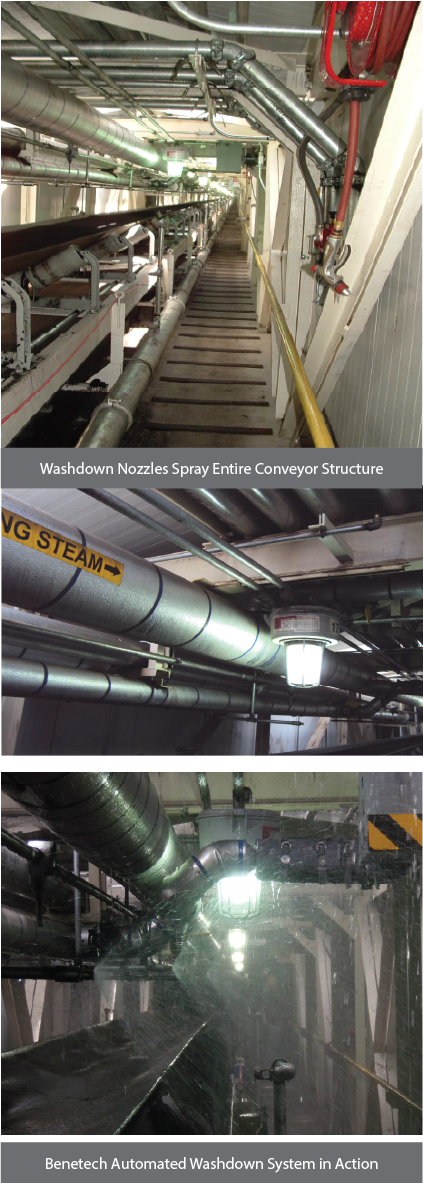

Benetech designed and installed an automatic fixed washdown system to provide washdown of coal fines and small coal particles from all surfaces, including walls, floors, structural ledges, walkways, galleries, conveyors, chutes, and piping. The system is composed of headers and nozzles divided into 16 approximately 40 feet zones and two control panels located at either end of the conveyor gallery. The nozzles, explicitly designed and oriented to wash down all surfaces within the zone. Benetech’s design provides adequate directional sprays for solid floor elevations to move water and effluents to the drains. In addition, the system prevents coal dust from being trapped and not washed off the structure and equipment. Benetech gave special attention to areas where the ceiling joins the walls, wind bracing joints, support columns, and the floors.

Successful Results

A specific sequential zone operating strategy was put in place to produce the best washdown results and minimize peak water requirements. As a result, Benetech reports washdown coverage of 95% or better for most areas. Overall, Benetech’s automated washdown system allows for better, more efficient housekeeping practices, lower labor costs, and ensures a safer operation.