Background

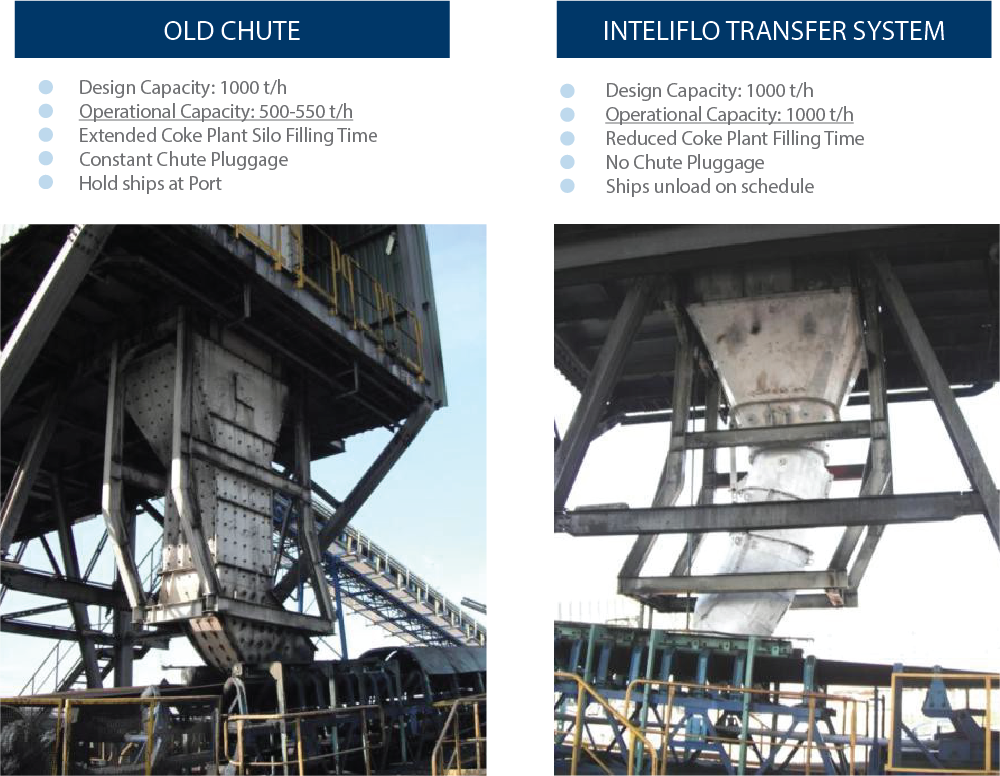

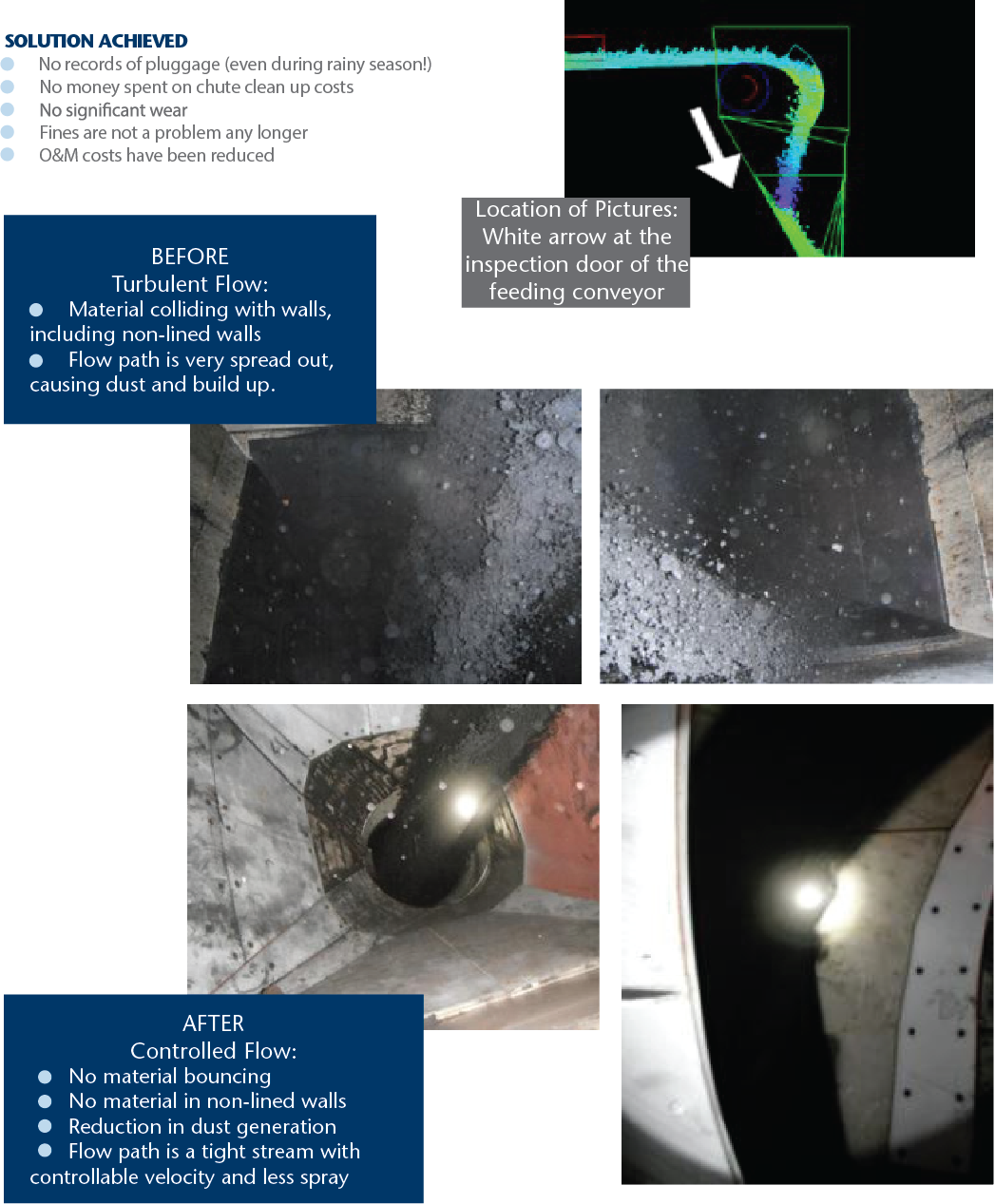

A full-service, comprehensive steel plant in Brazil was experiencing multiple problems with its chute. The constant issues meant the plant had to keep workers standing around the chute during operations to clean up spillage and ensure any pluggage was dealt with. Consequently, maintenance and housekeeping costs were very high. In addition, the vessel companies were charging the plant huge fines because they were taking too long to fill the silos. Therefore they were not able to get ships unloaded promptly. So the plant turned to Benetech Brazil to design a system that would:

- Improve their material handling process

- Eliminate the daily disruption of the Coke Plant

- Reduce Operating Cost

- Put an end to the enormous fines from ship demurrage

*Feeding belt is a reversing belt. Stacker/Reclaimer uses the same belt to store material in the yard and reclaims material to send to coke plant silos.