Best-in-Class Conveyor Components

Bulk material handling customers and processing industries depend on conveyor components and conveyor equipment. Conveyors and conveyor systems move products and materials along the supply chain from one location to another. Industrial conveyor systems add efficiency and safety as an integral part of modern material handling.

Where manual product transportation was time-consuming and hazardous to employees in the past, using today’s conveyor systems allows for fast and safe material flow, saving time and money, and keeping employees safer.

Benetech offers best-in-class Conveyor Components and accessories, including idlers, liners, v plows/v ploughs, motorized brushes, rotary brushes, brush cleaners, diagonal plows, conveyor guarding, and belt cleaners for bulk material handling for your conveyor systems and conveyor components equipment needs.

CONVEYOR BELT CLEANING SYSTEMS

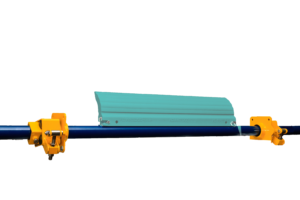

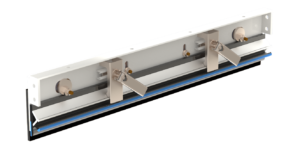

Benetech’s conveyor belt cleaning solutions include primary, secondary, and specialty belt cleaners that solve carry-back issues once and for all. Created to keep production moving and extend the life of your belt, our conveyor belt cleaning systems provide a superb and deep cleaning efficiency that minimizes maintenance.

Benetech’s conveyor belt cleaning solutions are made for all transported materials regardless of their hardness, shape, or abrasiveness. With our conveyor belt cleaning systems, your business can manage everything from wood chips, recycled paper, and garbage to iron pellets, coal, and crushed rock.

Flex-Arcs on our blade give our blade flexibility for a couple of reasons; most head pulleys are not round and can wobble. Belt cleaners need to have the flexibility to account for this wobbling and account for anything on the belt. Second, because of where these Flex-Arcs are located on our blade, the blade tip stays in constant contact with the belt, increasing the cleaning effectiveness of the edge.

Competitors’ flexibility is built into their blades by starting the tip of the blades thinner and getting thicker toward the bottom of the useable blade, thus more blade-to-belt contact and reducing cleaning efficiency.

- Primary Belt Cleaners

- BEP1

- BEP2

- Secondary Belt Cleaners

- BES1

- BXS5

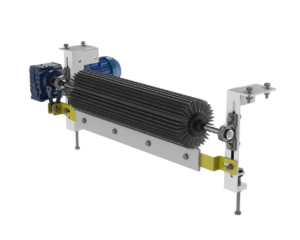

![conveyor components motorized brush cleaner]() Specialty Belt Cleaners

Specialty Belt Cleaners

- Motorized Brush Cleaner (rotary brush)

- V Plow

- Diagonal Plow

- Replacement Blades

- Standard (baby blue)

- High-Temperature (hot pink)

- Chemical-resistant (navy blue)

- Abrasion-resistant (yellow)

- Wash Box

CONVEYOR COMPONENTS BELT SUPPORT

IDLERS

- Troughing Idlers CEMA B, CEMA C, CEMA D, CEMA E Standard & Impact

- Designed with a triple labyrinth seal, Benetech’s rollers have advanced sealing protection and are sealed for life bearings that never require regreasing. Available in various belt widths and sizes, meeting all CEMA standards.

- Benetech’s troughing idlers are used to transition from an impact area or load zone. They can also be used to transition from a flat pulley area to picking or feeding area. Meeting all CEMA requirements and available in standard or impact, belt widths 24-72″, and troughing angles of 20, 35, & 45 degrees.

- Simple Slide Idlers

- Benetech’s Simple Slide Idler features roller frames that slide into place without the need to raise the belt or remove adjacent idlers, resulting in easy maintenance and excellent safety. In addition, the frames’ compact size allows for placement even in confined spaces, ensuring you have the belt support you need.

- Rated CEMA C, D, or E, the Simple Slide Idler is available with standard or wide-base roller frames. The frames require only 8″ (200mm) of width when 6″ rollers (150mm) are used.

- The Simple Slide Idler also uses either impact or steel rolls and comes in any belt width and troughing angle.

- Drop & Slide Idlers

- Benetech’s patent pending Drop & Slide Idler incorporates a retractable side support roller unit accessed from the conveyor’s serviceable side. When in the retracted position, the roller unit simply slides out from underneath the existing conveyor belt allowing for easy roller inspection or replacement.

- Carrying side conveyor belt idler and is used on the cargo-carrying side of the conveyor belt

- Placement of the idler is most common in transfer point or load zone areas but can be used anywhere on the carrying side of the conveyor belt.

- Unique design allows for a quick change installation from only one side

- Allows workers to stay in confined spaces for shorter periods

- Simple Slide Returns

- Benetech’s Simple Slide Returns allow for safe installation and removal of rollers from one side of the belt when access is restricted.

- In addition, the design of the frame assembly allows for placement even in confined spaces, allowing one person to change out the return roller quickly and safely.

IMPACT BEDS

- Warrior Impact Bed

- The Warrior Impact Bed includes a sturdy steel frame that stabilizes and supports the conveyor belt during loading, defending it from damage. In addition, the Warrior’s stiff, rigid frame and soft rubber bars cushion the belt and absorb impact.

- The Warrior Impact Bed also offers ‘fine-tune’ wing adjustment for optimum sealing, as well as wings and center sections that slide in and out for easy access. Plus, impact bar change-outs are quick, keeping downtime to a minimum. The result is longer belt life, no spillage, and lower operations and maintenance costs.

- Warrior Roll & Guide Support Bed

- The Warrior Roll & Guide Support Bed creates a seamless seal that helps eliminate dust and spillage in the load zone. The support bed uses low-friction slider bars on the wing sections and rollers in the center, minimizing belt drag while providing vital support at the edges. In addition, the adjustable wing sections ensure a flat, level surface for the conveyor belt and the load zone, allowing the sealing system to perform its best.

- Easy to install, maintain, and fit troughing angles, the Warrior Roll & Guide Support Bed increases skirtboard life, removes gaps between the skirtboard and seal, and stops crimping of interior skirt liners.

- The Warrior Roll & Guide Support Bed can include center standard or impact rollers; typical bars and beds are 48″ (1200mm). Custom lengths also are available.

CONVEYOR BELT TRACKING AND BELT MISALIGNMENT

Used widely in mining and other conveyor-related industries, these reliable, highly reactive conveyor belt tracking idlers continually outperform others on the market. Because they are made to operate under demanding conditions, the Benetech trackers prevent belt and structural damage caused by frame and guide rollers. The result is more savings and less downtime. Plus, the system’s brains are housed in the roller and cannot wear, so the trackers’ function will not fade over time.

The Benetech trackers accommodate conveyor belts ranging from 450mm to 2600mm in width.

- Benetech MaxTracker

- Benetech Troughing Tracker

- Benetech Reversible Tracker

CONVEYOR COMPONENTS – PREVENT SPILLAGE

XN Liner® Wearliners

The XN Liner® wearliners is placed in the conventional position inside the skirtboard while you can access the adjusting mechanism from the outside. As a result, you never need to enter the chute to remove the liner or make adjustments.

This patented technology gives you instant advantages, including quick, simple wear liner replacements; no confined entry requirements; easily visible adjustment with immediate performance results; reduced early wear and erosion of belt skirt rubber; extended life of usable steel/chrome; and no more cutting/welding of wearliners.

Benetech Skirting Seal Systems

- B Seal – a superior seal with a great price

- B-Plus Seal – B-Plus with polyurethane

- Classic Seal – a simple seal that gets the job done

- Classic Plus Seal – basic profile with a polyurethane addition that provides exceptional sealing for minimal belt-edge distances

- Classic Poly Seal – a solid, practical polyurethane seal that outlasts other products such as steel, UHMW, and rubber

- Load Zone Clamps

- Available as a 4′ or 6′ modular design, the standard clamp ensures the skirt provides a consistent seal and an economical solution for load-point spillage, as well as safe access and long service life. The bolt option comes in powder-coated, galvanized, or stainless steel; galvanized also includes a swivel-handle option.

Dust-Tight Conveyor Chute Inspection Doors

Heavy duty and simple to install, Benetech conveyor chute inspection doors let you achieve both necessary steps safely and efficiently. The doors’ distinctive design and proven technology provide you with complete and easy access for service and maintenance, as well as a tight seal against airborne dust.

An integral part of your material handling system, Benetech inspection doors feature:

- An innovative door-deflector panel for less material build-up on the door seal

- Grease fitting on pinned hinges for no play or locking up

- Resilient door seals are hidden in the groove for long-lasting service

- Ergonomic cam-action and never-seize closing latches with adjustable tension for suite operation requirements

- Heavy-duty handles that won’t bend

- Easy installation with a simple cut-and-weld or bolt-on process

The standard Benetech conveyor chute inspection door is mild steel (safety yellow) with an unlined deflector panel.

CONVEYOR COMPONENTS SAFETY

![Conveyor Components belt guard]() Conveyor Belt Guards

Conveyor Belt Guards

Staff at bulk material–handling plants spend considerable time moving mechanical parts and material flow. Benetech helps you protect your employees from moving parts and pinch points on the conveyor with conveyor belt guarding, especially around tail-pulley sections and gravity take-ups. Benetech’s customized, self-supporting conveyor belt guards are easy to install. They require no welding or cutting, and their modular bolt-together design makes the set-up simple.

They are equally easy to maintain, as well as built to last. Should staff access equipment, they can remove the conveyor belt guards in seconds with ergonomically friendly handles. Heavy-duty steel construction and powder coating further add extra years of use for your facility.

Conveyor Belt Covers

A corrosion-free, environmentally friendly, safe, and efficient conveyor belt cover. Protects the conveyor belt and components all year round from the elements (sun, wind, rain, and snow). Galvanized or stainless steel hoops with HDPE (white) or Polycarbonate (clear) covers.

Full, 1/2, or 3/4 covers in standard 4ft sections. Accessible from both sides of the conveyor, the anti-seize latches provide easy access. Simply remove the cable clips and raise the cover.

Return Idler Basket

Benetech’s Return Idler Basket prevents malfunctioning return idlers from falling below workers and equipment. It is easy to install; it requires no welding or cutting – beam-clamp assembly provides a simple snap-on. Its large openings also eliminate build-up. The lightweight design lets one person handle the guard, which can be snapped off to the service idlers or belts. Heavy-duty steel construction eliminates warping and bending, and a powder coating adds even more excellent durability.

We’re ready to assist you with optimal conveyor belt support and conveyor components for your transfer point solutions. Contact us at (630) 844-1300 today to speak with a Benetech specialist.

Conveyor Components Literature

| Products & Services - Catalog | Download |

| Products & Services - Line Card | Download |

| Idlers - Catalog | Download |

| Idlers - Line Card | Download |