Belt Cleaner Replacement Blades

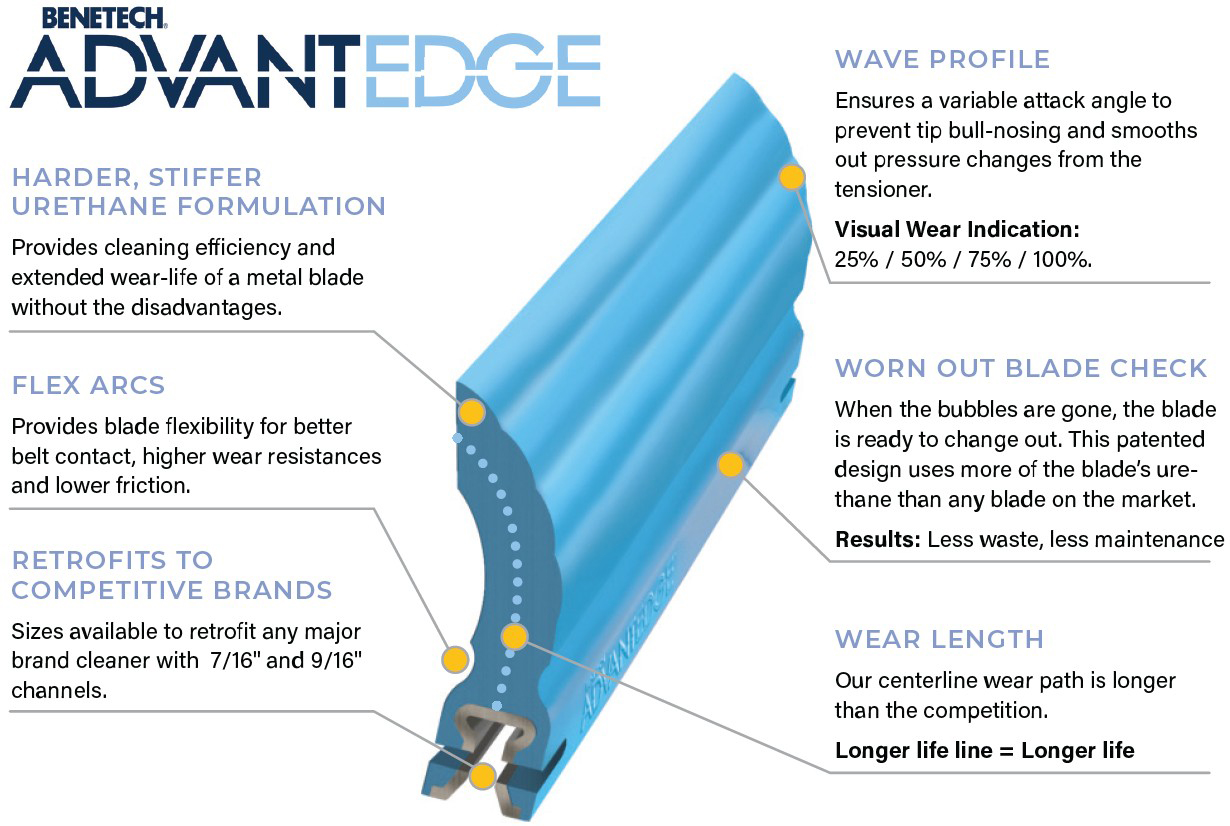

Benetech offers replacement belt cleaning blades for Benetech’s BEP1 primary cleaners and cleaners supplied by other manufacturers. Benetech’s replacement blades feature our patent-pending AdvantEdge blade technology combining the wearlife benefits of a metal blade in a safe polyurethane material, making Benetech the leader in high-performance urethane development.

Our blades are retrofit to match competitors’ blades that have 7/16-in or 9/16-in channels.

The main benefits of using our AdvantEdge belt cleaner blades for your material handling include:

Long-lasting Polyurethane

- Fewer blade changes are necessary – saving time and money

- Less maintenance required allowing your manpower to concentrate on other areas

A harder blade with a unique wave design

- The flexing feature minimizes differential pressure at the belt, ensuring more consistent contact and the elimination of carryback.

- The distinctive changing-profile design allows the blade to follow the belt contours, reduce blade-edge bull-nosing, and prevent blade separating and splitting.

- Unique wave profile indicates the percentage of wear over the lifetime of the blade – 25%, 50%, 70%, and 100%

More use of the blade for cleaning

- When standard industry urethane blades are worn, they are thrown away with 25% or more of the blade remaining; a worn AdvantEdge blade has only about 10% of the urethane left.

- This contrast in usage leads to notably greater wear life, less overall cost, and much less service maintenance.

Our replacement conveyor belt cleaner blades are color-coded to match performance to your application.

Benetech’s extensive experience and knowledge create powerful production advantages. We understand exactly what you need for efficient belt cleaning with a better blade that adapts, lasts longer, and ultimately saves you time and money. GUARANTEED!

Use AdvantEdge technology to achieve superior results for your material handling. Contact us at (630) 844-1300 today to inquire further about our BEP1 primary conveyor belt cleaning system or order your replacement conveyor belt cleaner blades.

Features

- A harder, stiffer urethane formulation provides the cleaning efficiency and the extended wear life of a metal blade without the disadvantages.

- The wave profile ensures a variable attack angle to prevent tip bull nosing and smooths out pressure changes from the spring tensioner.

- Replaces Benetech’s BEP1 primary belt cleaners, or retrofits to other brands

- Flex arcs provide flexibility for better belt contact, high wear resistance, and lower friction.

- Channel sizes: 7/16 in. or 9/16 in.

The Longest Lasting Blades on the Market

Standard (Baby Blue)

- Appropriate for 90% of applications

- Acid-resistant

- Materials: Coke, coal, steel/ore

- Temperature Rating: -20° to 160°F (-30° to 70° C)

High-Temperature (Hot Pink)

- For exposure to intermittent temperatures up to 450° (232° C)

- Materials: Clinker

- Temperature Rating (continuous): -40° to 375°F (-40° to 190° C)

Chemical-Resistant (Navy)

- Materials: Limestone

- Temperature Rating: -40° to 160°F (-40° to 70° C)

Abrasion-Resistant (Yellow)

- Materials: Hard rock, dry sand

- Temperature Rating: -20° to 160°F (-30° to 70° C)

Replacement Blades Literature

| Product Comparison - Retrofit Blades | Download |

| BEP1 Primary Cleaner - Flyer | Download |

| BEP2 Primary Cleaner - Flyer | Download |

| Belt Cleaners - Catalog | Download |